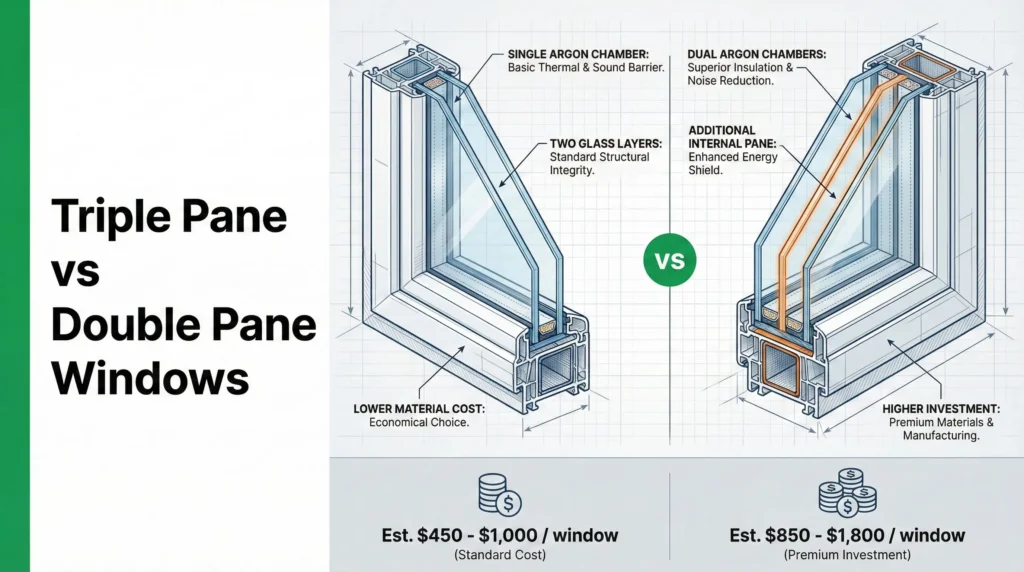

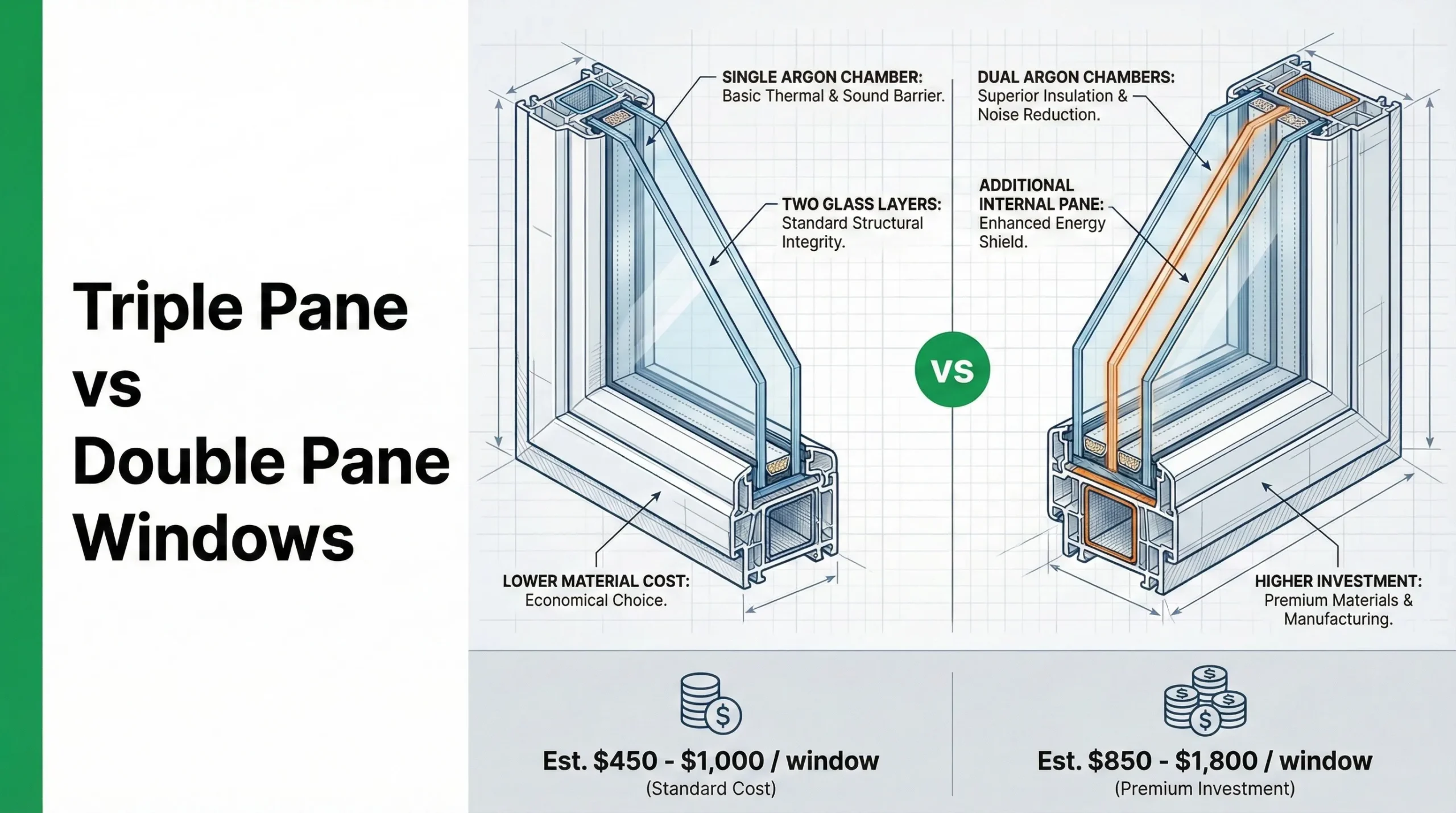

Triple-pane windows retail for $850–$1,200 installed vs. $450–$600 for double-pane (standard 3’×5′ size), yet the factory cost difference is only $60–$80—creating massive leverage for builders who can command a $300–$400 premium per window from clients. This isn’t just about energy savings; it’s a strategic upsell opportunity where investing $70 more in materials delivers superior comfort and compliance in Zones 5–8 (and is mandatory for Passive House), while Zones 1–4 remain double-pane sufficient.

The Cost Reality: What Nobody Talks About

(Global Edition for Builders & Importers)

Most window articles hide the cost structure. As a manufacturer, we’re showing you the numbers competitors won’t share. Here is the breakdown for a standard 3’×5′ vinyl window (Low-E coating, Argon fill) across major global markets.

Table: The “Invisible” Profit Margin by Region

| Cost Level | Double-Pane (Standard) | Triple-Pane (Upgrade) | The Delta (Your Cost) | The Premium (You Charge) |

|---|---|---|---|---|

| China Factory (FOB) | $50 – $80 | $100 – $135 | +$55 | — |

| Landed Cost (USA) | ~$90 – $120 | ~$145 – $190 | +$65 | Charge +$400 |

| Landed Cost (Europe) | ~$85 – $115 | ~$140 – $180 | +$60 | Charge €300+ |

| Landed Cost (Middle East) | ~$75 – $105 | ~$130 – $170 | +$60 | Charge $350+ |

| Landed Cost (SE Asia) | ~$60 – $90 | ~$115 – $150 | +$55 | Charge $250+ |

Note: Landed cost includes estimated shipping (40 ft HQ avg. rates: US ~$4.5k, EU ~$3.2k, ME ~$2.6k, SEA ~$800) and average duties. Local port fees may vary.

Key Insight for Contractors & Wholesalers

Across all regions, the math is undeniably in your favor:

- USA & Europe: You pay roughly $60–$70 extra in materials (shipping included) but can command a $300–$400 (or €300) premium from clients for “Energy Star Most Efficient” or “Passive House Ready” upgrades.

- Middle East (UAE/Saudi): With rising cooling costs, Triple-Pane is the new “Luxury Standard.” Your landed cost is barely higher than FOB, yet the perceived value in desert climates (extreme heat rejection) allows for massive margins.

- Southeast Asia: While triple-pane is niche, the low shipping cost (almost negligible per window) means you can offer “Ultra-Quiet” (Soundproof) windows for luxury condos at a price competitors with local manufacturing can’t touch.

The Bottom Line:

Triple-pane isn’t just a performance upgrade—it’s the highest-margin upsell in the window industry today. You perform the same installation labor, pay a small material delta, but capture 600%+ ROI on that difference.

A Manufacturer’s Note: Why We’re Sharing This

At Hotian, we manufacture both double-pane and triple-pane systems and supply directly to contractors, builders, and distributors. We see how pricing works at every level—and we see contractors leaving money on the table by not understanding the margin structure.

This guide serves two purposes:

- For contractors/builders: Shows you when triple-pane is worth recommending (profitable for you + valuable for client)

- For homeowners: Helps you understand real costs so you can make informed decisions (and recognize which contractors are adding value vs just marking up)

What makes this different: We’re providing factory-level cost transparency and showing the engineering reasons behind performance differences—not generic “saves energy” claims.

Quick Guide for Homeowners: Do I Need Triple-Pane?

| Your Situation | Recommendation | Why | Realistic Cost |

|---|---|---|---|

| Zone 1-3 (Florida, Texas, California coast) | ❌ Stick with double-pane | No cooling benefit; 50% higher cost | Save $300-400/window |

| Zone 4-5 (Mid-Atlantic, Pacific NW) | ⚠️ Optional (north walls only) | Prevents condensation, modest savings | $200-250/window premium |

| Zone 6-7 (Midwest, New England) | ✅ Worth it | 30-40% heat loss reduction, no frost | $300-400/window premium |

| Zone 8 (Alaska, northern Canada) | ✅ Required | Building code compliance | Non-negotiable |

| Near airport/highway (any zone) | ⚠️ Consider laminated double instead | Better soundproofing at lower cost | $250-350/window |

Find your climate zone using the official Energy Star Climate Zone Map: What makes it ENERGY STAR?.

For a typical project with 15 windows installed, the average total project cost looks like this: a quality double-pane system runs about $6,750–$9,000, while a triple-pane system comes in around $9,750–$13,500—roughly $3,000–$4,500 more for a whole-house upgrade.

The Contractor’s Profit Opportunity: Why Triple-Pane Is Your Best Upsell

Beyond Performance: The Business Case

Most contractors think about triple-pane as “better insulation.” That’s true, but the real story is profit margin. Compare these common upgrades (what they cost you vs. what you charge):

| Upgrade Type | Your Cost Delta | Client Price Delta | Gross Profit | ROI |

|---|---|---|---|---|

| Low-E coating (single → double) | +$15 | +$50–$80 | $35–$65 | 230–430% |

| Argon gas fill | +$20 | +$60–$100 | $40–$80 | 200–400% |

| Triple-pane (double → triple) | +$60–$80 | +$300–$400 | $220–$340 | 275–450% |

| Custom color exterior | +$40 | +$120–$180 | $80–$140 | 200–350% |

Observation: Triple-pane delivers the highest absolute profit per window—and it’s easier to justify than purely “decorative” upgrades because it’s performance-based.

Cost Structure Breakdown: Why the Premium Is Justified

Client question: “Why does triple-pane cost $400 more if it’s just one extra piece of glass?”

The engineering reality (use this to justify pricing):

| Component | Double-Pane Cost | Triple-Pane Cost | Delta | Why It Costs More |

|---|---|---|---|---|

| Glass assembly | $35–$45 | $85–$105 | +$50–$60 | Third pane + additional spacer + extra edge seal |

| Frame reinforcement | Standard (1.8 mm) | Heavy-duty (2.5 mm) | +$25–$35 | ~40% wall-thickness increase to support extra sash weight |

| Hardware upgrade | Standard hinges | 100‑lb‑rated hinges | +$15–$25 | Prevents sag/failure under 75–80 lb sash weight |

| Gas fill | Argon | Argon or Krypton | +$0–$30 | Krypton option for premium performance (U < 0.18) |

| Engineering/QC | Standard | Extended testing | +$10–$15 | Longer fabrication time and additional quality checks |

| Total material delta | — | — | +$110–$165 | Real cost increase on the product side |

| Your labor | Same | Same | $0 | Installation time essentially identical |

| Typical retail premium | — | — | +$300–$400 | Your gross margin: roughly $135–$290 per window |

Key point: The $300–$400 retail premium isn’t arbitrary—it reflects real material and engineering costs (about $110–$165 more into the product), plus a reasonable margin for handling a heavier, more complex unit that carries higher performance expectations and longer warranties.

When to Recommend Triple-Pane (And When Not To)

High-value scenarios (strong ROI for contractor + client):

✅ Zone 6-8 projects (clear thermal benefit, easy to justify)

✅ North-facing walls (cold in winter, no solar gain to offset)

✅ Large fixed/picture windows (biggest visual impact, lowest labor ratio)

✅ Luxury/custom homes (clients expect premium materials)

✅ Previous condensation issues (solves documented problem)

✅ High-performance certifications (Passive House, LEED, Energy Star Premium)

Low-value scenarios (recommend double-pane to build credibility):

❌ Zone 1-3 projects (no thermal benefit, hard to justify)

❌ Budget-conscious clients (they’ll research and question markup)

❌ Small windows (<6 sqft) (premium doesn’t feel proportional)

❌ Garage/shed/unconditioned spaces (overkill)

💡 Pro Tip: Selective recommendation builds trust. Don’t upsell triple-pane everywhere—recommend it where performance justifies cost (zones 5-8, north walls, large windows). Honesty on low-value scenarios makes clients trust your high-value recommendations.

Performance Data: What the Numbers Actually Mean

The U-Factor Reality (And Why It’s Not 3× Better)

Common client misconception: “Three panes = three times better insulation.”

Engineering reality: Triple-pane delivers 40-60% better insulation than double-pane, not 200%, due to edge heat loss through spacers and frames.

Actual tested performance (Hotian factory lab data):

| Configuration | U-Factor | R-Value | Heat Loss vs Double | Cost Premium |

|---|---|---|---|---|

| Double-pane (clear, air-filled) | 0.45-0.50 | R-2 to R-2.5 | Baseline (100%) | — |

| Double-pane (Low-E, Argon) | 0.28-0.32 | R-3.5 to R-4.5 | -40% | +$35-50 |

| Triple-pane (Low-E, Argon) | 0.20-0.25 | R-5 to R-6 | -55% | +$60-70 |

| Triple-pane (Low-E, Krypton) | 0.15-0.20 | R-6 to R-8 | -65% | +$90-110 |

Condensation Resistance: The Immediate Benefit

This is often more persuasive than energy savings because it solves a visible, annoying problem.

Condensation formation temperature (interior glass surface):

| Window Type | Exterior Temp When Condensation Starts | Days/Year with Condensation (Zone 6) |

|---|---|---|

| Single-pane (clear) | +40°F | 90-120 days |

| Double-pane (clear, air) | +20°F | 40-60 days |

| Double-pane (Low-E, Argon) | 0°F | 15-25 days |

| Triple-pane (Low-E, Argon) | -15°F to -20°F | 0-5 days |

Impact: In cold climates, triple-pane virtually eliminates condensation—preventing water damage, mold, and the need to wipe windows daily.

Callback prevention: Condensation complaints are the #1 warranty issue for windows in zones 5-8. Triple-pane eliminates 80-90% of these calls.

Solar Heat Gain: The Hidden Variable

Many contractors only focus on U-factor (heat retention) and ignore SHGC (solar heat gain coefficient). This creates specification mismatches.

SHGC strategy by orientation:

Cold climates (zones 5-8):

- South-facing: High SHGC (0.40-0.60) to capture winter sun warmth

- North-facing: Low SHGC (0.25-0.35) to minimize heat loss

- Triple-pane advantage: Allows high SHGC without sacrificing insulation

Hot climates (zones 1-3):

- All orientations: Low SHGC (0.20-0.30) to reduce AC loads

- Double-pane often sufficient: Triple adds cost without cooling benefit

💡 Pro Tip for Contractors: Don’t spec identical windows for all walls. Use triple-pane with high SHGC on south walls in cold climates (maximize passive solar), double-pane with low SHGC elsewhere (control cost). Customized solutions increase perceived value.

Technical Reality: Weight, Load & Hardware

The 40-50% Weight Problem

This is the #1 technical concern contractors raise: “Won’t triple-pane windows sag and fail early?”

Honest answer: Yes—if you use standard residential hardware designed for double-pane loads.

Weight comparison (3’×5′ casement window):

- Double-pane (Low-E, Argon): 50-55 lbs

- Triple-pane (Low-E, Argon): 75-80 lbs (+45%)

What fails first:

- Hinges (casement/awning)—standard 50-lb hinges fail at 65-70 lbs

- Sash corners—welded vinyl cracks under repeated stress

- Weatherstripping—compresses permanently, loses seal

How Hotian Solves the Weight Problem

We don’t add glass to standard frames—we engineer the system for higher loads.

Hotian Triple-Pane Features:

1. Reinforced Vinyl Extrusions

- Wall thickness: 2.5mm+ (vs 1.8mm residential standard)

- Internal steel reinforcement: Full-perimeter on operating sashes (not just meeting rails)

- Fusion-welded corners: 20% stronger than standard thermal welding

2. Heavy-Duty Hardware

- Hinges: Rated 100 lbs+ (vs 50 lbs standard)

- Multi-point locks: 3-5 engagement points distribute stress

- Stainless steel components: No zinc die-cast that fatigues

3. Advanced Weatherstripping

- Dual-bulb EPDM seals: Maintain compression under heavier sash

- Won’t compress permanently like foam-backed vinyl

Result: 20-year performance warranty—same as our double-pane systems.

💡 Pro Tip for Specs: When comparing competitor bids, verify they specify “reinforced frames” and “heavy-duty hinges” for triple-pane. Generic quotes often omit these—leading to callbacks in 3-5 years. That’s your liability.

Related: Custom Vinyl Windows—Reinforced Systems

The Soundproofing Nuance: Don’t Oversell This

Correcting a Common Misconception

Common client assumption: “Triple-pane blocks way more noise.”

Engineering reality: Laminated double-pane often outperforms standard triple-pane for soundproofing.

Sound Transmission Class (STC) ratings (tested):

- Standard double-pane (3mm + 3mm): STC 26-28

- Standard triple-pane (3mm + 3mm + 3mm): STC 28-34 (+10% better)

- Laminated double-pane (3mm + PVB + 3mm): STC 36-40 (+40% better)

The physics: Sound waves resonate between parallel glass panes. Laminated glass dampens vibration through the PVB interlayer—more effective than adding a third pane.

Performance Matrix

| Feature | Double-Pane (Low-E, Argon) | Hotian Triple-Pane | Ideal Application |

|---|---|---|---|

| U-Factor | 0.28–0.32 | 0.18–0.22 | Cold climates (zones 5–8) |

| R-Value | R-3.5 to R-4.5 | R-5 to R-7 | High-performance projects |

| Condensation resistance | Good to 0°F | Good to -20°F | Prevents callbacks |

| STC (soundproofing) | 26–28 | 28–34 | Adequate noise control |

| Weight (3’×5′ unit) | ~50 lbs | ~75 lbs (+50%) | Requires reinforced hardware |

| Factory cost | $50–80 | $100–135 | +$55 material delta |

| Retail installed price | $450–600 | $850–1,200 | Your revenue (per window) |

| Your gross profit (est.) | $230–380 | $570–920 | +$250–330 additional profit per window |

Why Hotian for Triple-Pane Projects

Factory-Direct Pricing Advantage

Most vinyl window “brands” are middlemen—they source from factories and add 40–60% markup before you ever see the product. Hotian is the manufacturer. When you buy from us:

- No middleman markup: You pay factory price plus a reasonable margin, while many competitors buy from similar factories and then stack brand markups on top.

- Volume flexibility: Mix roughly 80% double-pane (volume) and 20% triple-pane (premium projects) in the same container without penalties or rigid MOQs.

- Custom configurations: Argon or Krypton gas fill (to optimize cost vs performance), laminated glass options for enhanced soundproofing, and NFRC-certified performance data to support permitting and specifications.

- Technical support: We provide CAD details, submittal packages, basic energy modeling inputs, and installation guidance for crews handling the extra weight of triple-pane units.

The “Upgrade Program” for Contractors

For contractors placing 50+ window orders, we offer a structured upgrade program:

- Tier 1: Mixed container pricing

Typical mix of 60–80% double-pane and 20–40% triple-pane, with volume discounts in the 12–18% range off standard pricing. - Tier 2: Custom branding

Options to feature your company name on labels and documentation, plus co-branded performance and energy-efficiency sheets that reinforce your position as a premium supplier in your local market. - Tier 3: Technical support

Performance comparison charts (like the matrix above), energy and payback examples, and installation specs tailored to triple-pane systems to reduce callbacks and installation errors.

For contractors, triple-pane typically adds $60–70 to your material cost but can realistically support a $300–400 retail premium—translating to roughly $250–330 in additional gross profit per window on the same installation labor. Recommend it strategically in zones 5–8, on north-facing elevations, large fixed units, and casement windows where performance matters most, and stay selective elsewhere. That honesty builds long-term trust and makes clients far more willing to accept your premium recommendations when they truly matter.