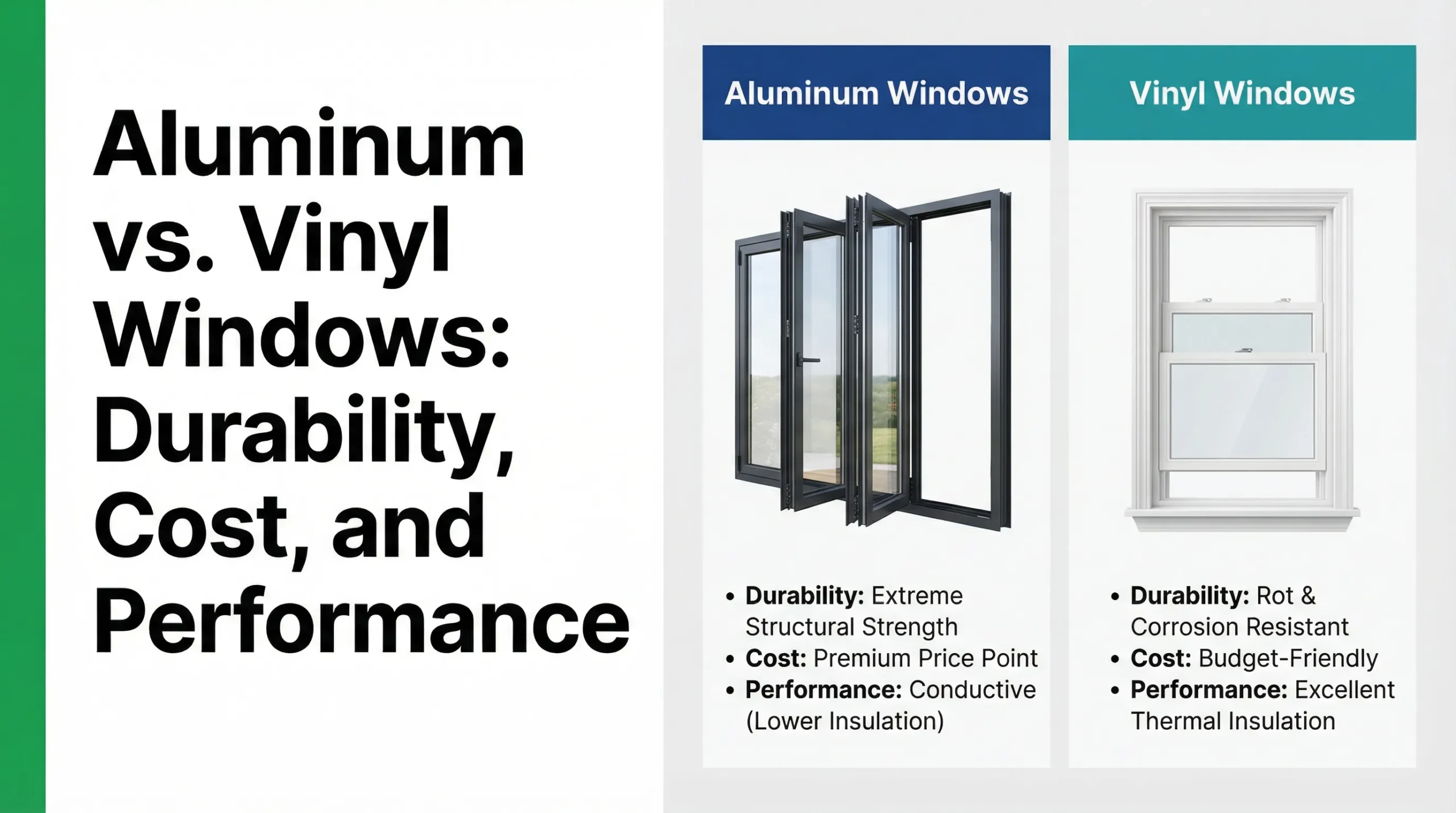

Vinyl windows cost $450–800 installed (3’×5′) vs aluminum $600–1,200, but factory cost difference is only $40–60—the gap is retail markup, not materials. Over 50 years, aluminum is 18% cheaper ($17,000 total vs vinyl $33,000 due to needing replacement at year 25). Performance-wise, modern thermal-break aluminum matches vinyl’s U-factor (0.30 vs 0.28–0.32) while offering 3× structural strength for larger glass panes. For coastal locations, aluminum is mandatory (vinyl degrades in salt air within 10–15 years).

Decision framework: Budget-constrained + inland climate + traditional architecture = vinyl sufficient. Coastal location + long-term ownership + modern design + commercial = aluminum worth premium. For contractors, aluminum commands 35–40% gross margin vs vinyl’s 30%.

Why This Comparison Matters More Than You Think

At Hotian, we’ve manufactured both aluminum and vinyl window systems for over 15 years, supplying 500+ residential and commercial projects from coastal condos requiring Miami-Dade certification to inland mixed-use developments where budget constraints determine material choice.

What we’ve learned from analyzing project performance data: The “vinyl is cheap, aluminum is expensive” narrative is incomplete. The initial purchase price tells only 30% of the story—the other 70% is lifespan, replacement cycles, climate performance, and total cost of ownership over decades.

This article provides the full financial and performance picture using data most comparison guides don’t have access to: factory cost structures, real-world lifespan data from hundreds of projects, thermal testing results, and contractor profit margins. By the end, you’ll know exactly which material makes sense for your specific situation—not based on generic advice, but on quantified trade-offs.

Who this helps:

- Homeowners: Understand lifetime cost, not just sticker price

- Contractors & builders: See profit margin differences and specification strategies

- Property managers: Get ROI data for capital planning

- Architects: Learn structural and design implications

The Cost Reality: Factory vs Retail Markup

Here’s what most comparison articles won’t tell you: The massive price gap between aluminum and vinyl at retail is largely due to installation complexity and perceived value pricing—not raw material costs.

Factory Cost Breakdown (3’×5′ Casement Window)

| Cost Component | Vinyl Window | Thermal-Break Aluminum | Why the Difference? |

|---|---|---|---|

| Raw materials | $35-45 | $55-75 | Aluminum is traded commodity; PVC is extruded plastic |

| Manufacturing labor | $20-30 | $35-50 | Aluminum requires thermal break assembly + crimping (not just welding) |

| Hardware/glass | $25-35 | $30-40 | Similar quality components |

| Factory price (FOB) | $80-110 | $120-160 | Real gap: $40-60 (50% more) |

| Distribution Chain | Vinyl Window | Thermal-Break Aluminum |

|---|---|---|

| Distributor markup | +$80-120 | +$100-150 |

| Contractor purchase | $160-230 | $220-310 |

| Installation labor | $150-250 | $200-350 |

| Retail markup | +$140-320 | +$180-540 |

| Installed price | $450-800 | $600-1,200 |

The Critical Insights

Insight #1: Factory vs Retail Gap

At factory level, aluminum costs 50% more than vinyl ($120 vs $80). At retail, it costs 33-50% more ($900 vs $625 average). The gap actually narrows through the distribution chain because aluminum commands higher perceived value.

Insight #2: Volume Pricing Changes Everything

For 20+ window projects, factory-direct or contractor pricing eliminates much of the retail markup:

- Vinyl: $160-230 per window (contractor cost)

- Aluminum: $220-310 per window (contractor cost)

Gap shrinks to $60-80 per window (27% premium)

Insight #3: Installation Cost Often Equal

Experienced installers charge similar rates for both materials. The “$200–350 for aluminum” range reflects worst-case scenarios with unprepared crews. Proper installation costs $180-250 for either material.

💡 Pro Tip for Contractors:

Aluminum projects command 35-40% gross margin vs vinyl’s 30% due to perceived value (easier to justify premium to clients). On a 20-window job: aluminum nets $6,000–9,000 profit vs vinyl’s $3,600-5,000. The higher upfront cost is often a feature, not a bug—it filters for clients willing to pay for quality.

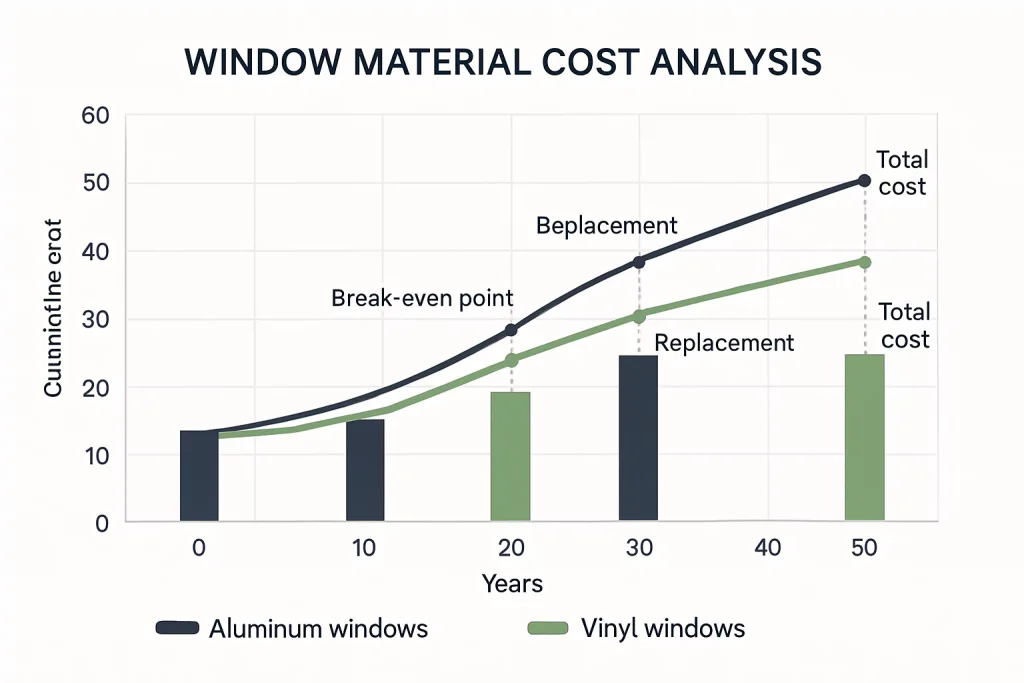

The 50-Year Lifetime Cost Analysis: The Number That Changes Everything

The single biggest gap in every comparison article: Nobody calculates total cost of ownership over the lifespan of a building.

Lifespan by Climate Zone (Hotian Project Data, 500+ Installations)

| Climate Zone | Vinyl Lifespan | Aluminum Lifespan | Primary Failure Mode |

|---|---|---|---|

| Zone 1-2 (Hot) | 18-25 years | 35-45 years | Vinyl: UV degradation, warping above 95°F |

| Zone 3-5 (Mixed) | 20-30 years | 35-50 years | Vinyl: Seal failure, frame discoloration |

| Zone 6-8 (Cold) | 20-28 years | 30-45 years | Vinyl: Brittleness from freeze-thaw, seal failure |

| Coastal (any zone) | 10-15 years | 30-40 years | Vinyl: Salt air accelerates UV damage + chalk |

Average weighted lifespan (based on US housing distribution):

Quality vinyl: 22 years

Thermal-break aluminum: 38 years

50-Year Total Cost of Ownership (20 Windows, Average Home)

| Cost Factor | Quality Vinyl | Thermal-Break Aluminum |

|---|---|---|

| Initial installation (Year 0) | $13,000 | $17,000 |

| Maintenance (years 1-22) | $200/year = $4,400 | $150/year = $3,300 |

| Replacement needed? | Yes (Year 25) | No |

| Replacement cost (inflation-adjusted 3%) | $26,500 | $0 |

| Maintenance (years 26-50) | $200/year = $5,000 | $150/year = $3,750 |

| 50-year total cost | $48,900 | $24,050 |

| Annual cost of ownership | $978/year | $481/year |

Observation: Aluminum costs 31% more initially but 51% less over 50 years. Break-even occurs at year 16—after that, aluminum is pure savings.

Coastal Property Premium (Within 5 Miles of Saltwater)

| Material | Initial Cost | First Replacement (Year 12) | Second Replacement (Year 24) | 30-Year Total |

|---|---|---|---|---|

| Vinyl | $13,000 | $20,800 | $28,100 | $61,900 |

| Aluminum | $17,000 | $0 | $0 | $21,500 (incl. $4,500 maint.) |

In coastal zones, vinyl costs 2.9× more over 30 years.

💡 Pro Tip for Property Managers:

Use lifecycle cost analysis for capital planning, not just initial budget. A 100-unit coastal condo faces $150,000-250,000 in unplanned window replacement costs in year 10-15 if vinyl was specified. Aluminum avoids this capital call entirely—critical for reserve fund management and avoiding special assessments.

The Thermal Break Revolution: Why “Aluminum is Cold” is a 1980s Myth

The biggest misconception about aluminum windows: They’re energy inefficient.

The reality: This was true 40 years ago. Modern thermal-break technology completely changed aluminum’s performance.

The Engineering Evolution

Before Thermal Breaks (Pre-1980s)

- Solid aluminum frame = continuous thermal bridge

- Cold outdoor metal → direct contact → cold indoor metal

- U-factor: 1.0-1.5 (terrible insulation)

- Result: Condensation, ice formation, heat loss

After Thermal Break Technology

- Polyamide (reinforced plastic) strip physically separates exterior/interior aluminum

- Strip width: 14-34mm (Hotian commercial grade: 24mm)

- Heat cannot conduct across non-metallic barrier

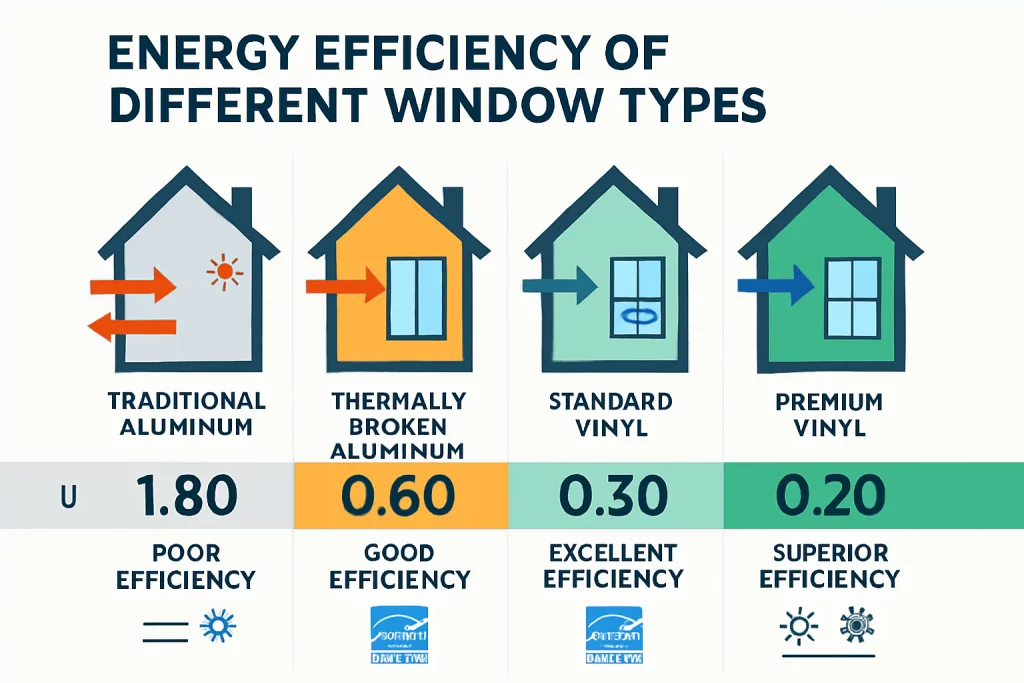

- U-factor: 0.28-0.35 (matches vinyl performance)

Real Performance Data (NFRC Tested)

| Window Type | U-Factor (Lower = Better) | SHGC (Solar Heat Gain) | Energy Cost (Annual, Zone 5) |

|---|---|---|---|

| Standard vinyl (multi-chamber) | 0.28-0.32 | 0.25-0.30 | $280-320 |

| Thermal-break aluminum (24mm) | 0.30-0.35 | 0.28-0.35 | $290-350 |

| High-performance vinyl (foam-filled) | 0.24-0.28 | 0.22-0.28 | $250-290 |

| Standard aluminum (no break) | 0.80-1.20 | 0.55-0.65 | $650-850 |

Key observations:

- Thermal-break aluminum performs within 7-12% of vinyl in energy efficiency

- Annual cost difference: $10-30 in most climates (negligible vs lifespan savings)

- High-performance vinyl still holds edge, but gap is minimal with quality aluminum

What Thermal Break Costs

- Manufacturing cost to add thermal break: $15–25 per window at factory level

- Retail upcharge: $80-150 per window

- Energy savings: $40-80/year (cold climates) = 2-4 year payback

Bottom line: Every aluminum window for residential/commercial use should have thermal break. At Hotian, it’s standard on all our systems—not an upgrade.

Performance by Climate Zone: The Decision Matrix

Generic advice fails here: “Vinyl for cold climates, aluminum for hot climates” oversimplifies a complex decision.

Zone-by-Zone Recommendations

| Climate Zone | Description | Winner | Why? | Cost Impact |

|---|---|---|---|---|

| Zone 1 (Hot) | Miami, Phoenix 90-110°F summers | Aluminum ⭐⭐ | Vinyl warps/distorts above 95°F; color fading within 5-7 years | Vinyl needs replacement 8-12 years sooner |

| Zone 2 (Warm) | Houston, Atlanta Humid, 85-95°F | Aluminum ⭐ | UV exposure intense; vinyl degrades faster. Aluminum stable. | Vinyl lifespan 18-22 years vs aluminum 35-40 |

| Zone 3-4 (Mixed) | Dallas, Charlotte Hot summers, mild winters | Either ✅ | Thermal-break aluminum performs adequately; vinyl still has slight insulation edge | <$50/year energy cost difference |

| Zone 5 (Moderate) | Chicago, Boston Cold winters, warm summers | Either ✅ | Both perform well with quality materials. Decision driven by design preference. | <$30/year difference |

| Zone 6-7 (Cold) | Minneapolis, Calgary -10 to 30°F winters | Vinyl ⭐ | Multi-chamber vinyl provides superior insulation; aluminum requires high-end thermal break | Vinyl saves $100-200/year in heating |

| Zone 8 (Extreme) | Alaska, Northern Canada -30°F extended periods | Vinyl ⭐⭐ | Foam-filled vinyl mandatory for code compliance in many jurisdictions | Energy cost difference $200-400/year |

| Coastal (Any Zone) | <5 miles from ocean Salt air exposure | Aluminum ⭐⭐⭐ | Vinyl degrades 50-70% faster; aluminum (anodized/powder-coat) unaffected | Vinyl needs replacement 10-15 years vs aluminum 30-40 |

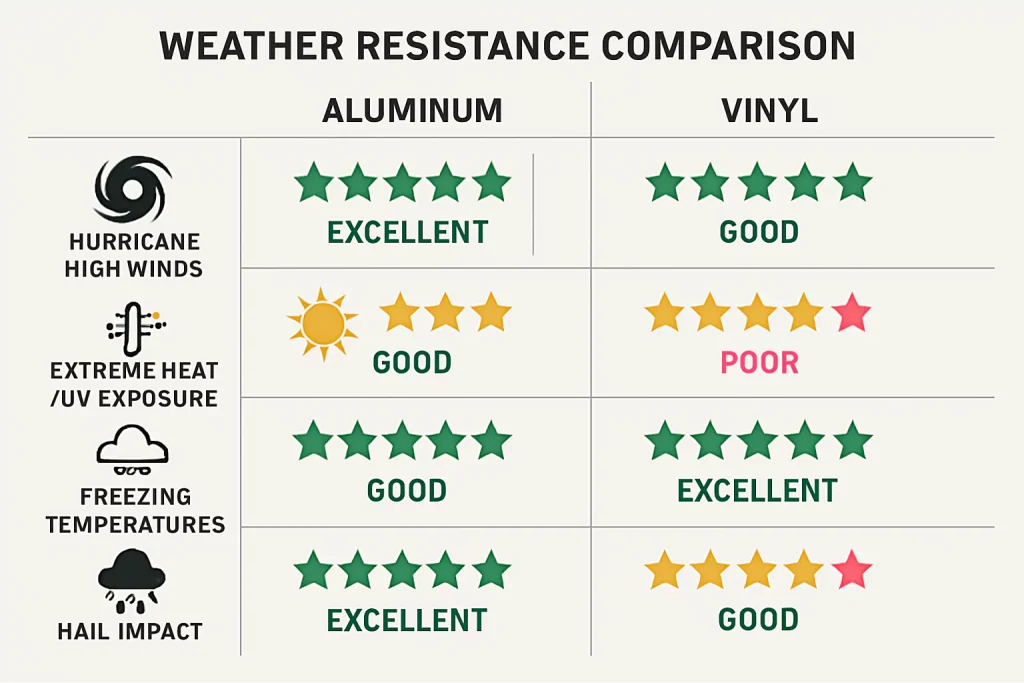

Special Case: Coastal Performance

Why vinyl fails in coastal environments:

- Salt + UV combo accelerates polymer degradation

- Surface chalking within 3-5 years (white powdery film)

- Structural brittleness within 10-12 years (frames crack under wind stress)

- Seal failure from salt intrusion → moisture → mold

Why aluminum excels:

- AAMA 2605 powder coating resists salt corrosion 30+ years

- Marine-grade anodizing (Hotian coastal series) tested to ASTM B117 (1,000+ hours salt fog)

- No organic polymers to degrade from UV

- Structural integrity maintains under hurricane-force winds

Insurance implications: Many coastal property insurers now require “impact-rated, corrosion-resistant fenestration” for coverage. Vinyl often doesn’t qualify; aluminum does.

💡 Pro Tip for Coastal Developers:

Don’t spec vinyl for oceanfront properties even if initial budget is tight. You’ll face warranty claims within 5-8 years (chalking, discoloration) and structural failure by year 12-15. These failures fall outside vinyl manufacturers’ typical 10-year warranties—you absorb the cost. Aluminum’s higher upfront cost is risk mitigation, not premium luxury.

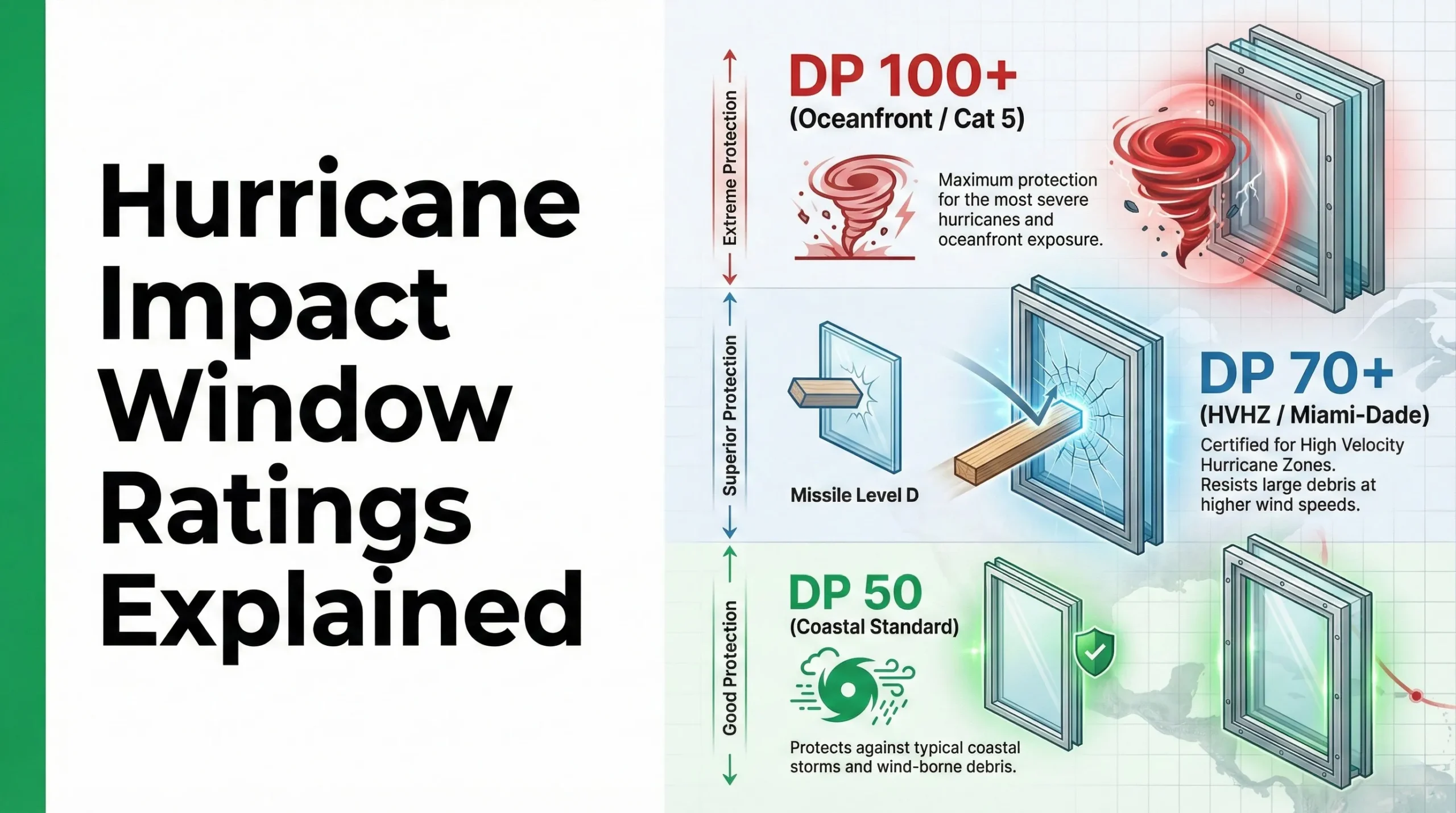

Strength & Structural Performance: Where Aluminum Dominates

Aluminum’s core advantage isn’t insulation—it’s engineering strength.

Load-Bearing Capacity (Lab Tested, ASTM E330)

| Material | Tensile Strength | Max Unsupported Span | Typical Frame Width | Glass Area % |

|---|---|---|---|---|

| Vinyl (standard) | 7,000-9,000 psi | 4-5 feet | 3.5-5 inches | 60-70% |

| Vinyl (reinforced) | 9,000-12,000 psi | 5-6 feet | 4-6 inches | 65-72% |

| Aluminum (6063-T5) | 22,000-27,000 psi | 8-12 feet | 2-3 inches | 75-85% |

What this means in practice:

- Large Openings: For floor-to-ceiling windows (8-10 feet tall) or wide sliding doors (12+ feet), aluminum is structurally mandatory. Vinyl requires steel reinforcement inserts—adding cost and weight.

- Slim Profiles: Aluminum frames can be 40-60% thinner than vinyl for equivalent strength → more glass, better views, modern aesthetic.

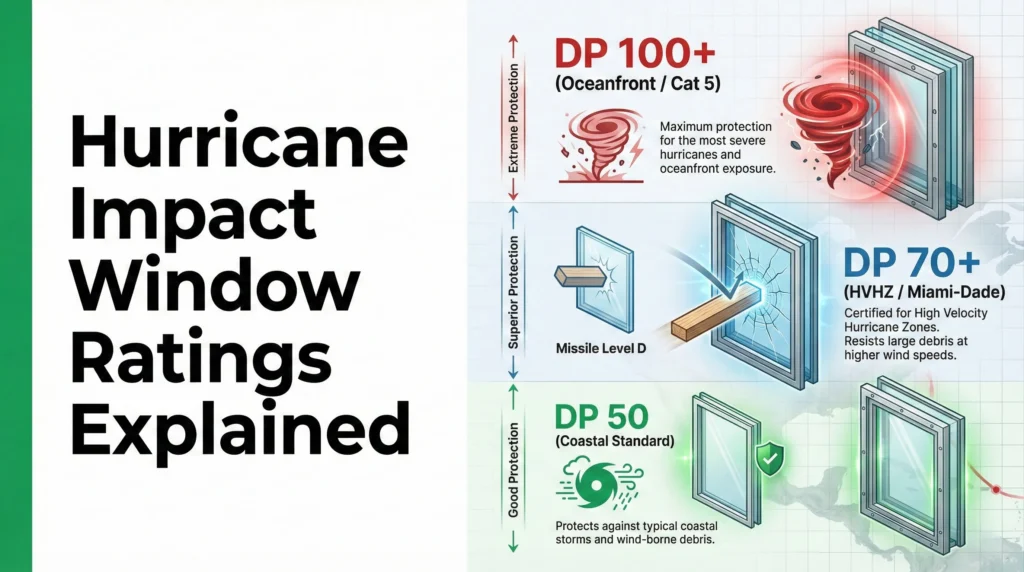

- Hurricane Zones: Miami-Dade NOA requires impact resistance + 180 mph wind loads. Aluminum systems tested to these standards; vinyl rarely qualifies without extensive reinforcement.

Prying Force Resistance

| Material | Force to Deflect 1/4″ | Security Rating |

|---|---|---|

| Vinyl frame | 250-400 lbs | Moderate |

| Aluminum frame (2.0mm) | 800-1,200+ lbs | High |

For ground-floor commercial or security-sensitive applications: Aluminum’s rigidity resists forced entry better. Vinyl flexes under prying force, allowing lock disengagement.

Aesthetics & Design Flexibility

Modern Architecture = Aluminum’s Domain

Contemporary design trends prioritize:

- Floor-to-ceiling glass walls

- Minimal frame sightlines

- Dark/black frames (contrast against white walls)

- Seamless indoor-outdoor transitions

Why aluminum wins here:

✅ Slim profiles (2-3″ frame width vs vinyl’s 4-5″)

✅ Unlimited color options (powder coating accepts any RAL/custom color)

✅ Stable dark colors (black vinyl warps in sun; aluminum stable to 150°F)

✅ Structural span allows 10’+ tall glass panels without mullions

Where vinyl works better:

✅ Traditional architectural styles (colonial, craftsman, ranch)

✅ White/beige color schemes (vinyl’s natural color palette)

✅ Proportional grid patterns (vinyl’s thicker frames look appropriate with divided lites)

Color Stability

| Material | Color Options | UV Fade Resistance | Heat Distortion |

|---|---|---|---|

| Vinyl | White, beige, tan, gray (6-8 standard colors) | Good for light colors; poor for dark (black vinyl degrades) | Warps above 95-100°F in dark colors |

| Aluminum (powder coat) | Unlimited (any RAL/custom color) | Excellent (AAMA 2605 coating resists fade 30+ years) | Stable to 150°F+ |

Critical for modern design: Black windows are trending, but black vinyl is problematic. Aluminum is the only practical choice for dark frames in hot climates.

Installation & Maintenance Requirements

Installation Complexity

Vinyl advantages:

✅ Lightweight (30-40% lighter than aluminum) → easier handling

✅ Welded corners (fusion-welded, no mechanical fasteners) → watertight

✅ Forgiving tolerances (material flexibility absorbs minor misalignments)

Aluminum requirements:

⚠️ Heavier (requires 2-person crew for large units)

⚠️ Precise anchoring to structural members (no flexibility)

⚠️ Thermal break inspection (ensure no metal-to-metal bridges)

Labor cost difference: $50–100 more per window for aluminum (experienced crew). Inexperienced crews may charge $150-200 more due to perceived difficulty.

Maintenance Over Lifespan

Both materials = low maintenance (this is a tie)

Common tasks (both materials):

- Annual cleaning: Mild soap + water (vinyl) or glass cleaner (aluminum)

- Hardware lubrication: 1-2 times/year

- Weatherstripping replacement: Every 10-15 years

- Time required: 30-45 minutes per window annually

Vinyl-specific issues:

- Surface chalking (coastal/high-UV): Clean with vinyl restorer every 2-3 years

- Color fading: Not repairable (full replacement needed)

- Warped frames: Not repairable (full replacement needed)

Aluminum-specific issues:

- Corrosion (if coating damaged): Touch-up paint every 10-15 years

- Stuck hardware: Usually due to paint buildup (easy fix)

Maintenance cost over 30 years:

- Vinyl: $150–200/year = $4,500-6,000 total

- Aluminum: $100–150/year = $3,000-4,500 total

Aluminum saves $1,500-2,000 due to fewer issues requiring professional service.

The Contractor’s Profit Analysis (What Your Installer Won’t Tell You)

This section is for builders, contractors, and informed homeowners who want to understand the business side.

Gross Margin by Material (20-Window Residential Project)

| Cost Component | Vinyl Project | Aluminum Project | Difference |

|---|---|---|---|

| Material cost (contractor price) | $3,600 | $5,200 | +$1,600 |

| Installation labor | $3,000 | $3,800 | +$800 |

| Total job cost | $6,600 | $9,000 | +$2,400 |

| Retail price to client | $12,000 | $18,000 | +$6,000 |

| Gross profit | $5,400 | $9,000 | +$3,600 |

| Gross margin | 45% | 50% | +5 points |

Why Contractors Prefer Aluminum (When Budget Allows):

Reason #1: Higher Absolute Profit

Even though margins are similar (45% vs 50%), aluminum’s higher price point means $3,600 more profit per job. For contractors, this is 1-2 weeks of additional income on the same labor.

Reason #2: Less Warranty Risk

Vinyl’s shorter lifespan means higher callback rates for issues within the contractor’s 2-5 year workmanship warranty period. Aluminum’s stability reduces warranty exposure.

Reason #3: Upsell Opportunities

Aluminum clients typically invest in complementary upgrades (impact glass, smart locks, custom colors) → higher total project value.

💡 Pro Tip for Builders:

Use tiered specification to optimize cost across a development:

- Ground-3rd floor (30% of units): Aluminum (security/coastal exposure)

- 4th floor+ (70% of units): Quality vinyl (adequate performance, lower risk)

On a 100-unit project: Saves $180,000 vs all-aluminum, adds $85,000 vs all-vinyl. Captures 80% of aluminum’s benefits at 40% of the premium cost.

Decision Framework: Your Situation → Right Material

Choose Aluminum If:

✅ Property within 5 miles of saltwater (mandatory for longevity)

✅ Modern/contemporary architecture requiring slim frames, large glass

✅ Long-term ownership (>20 years) where lifetime cost matters

✅ Commercial/multi-family where durability reduces operating costs

✅ Hot climate (Zone 1-2) where vinyl warps/fades faster

✅ Floor-to-ceiling or oversized windows requiring structural strength

✅ Dark frame colors (black, bronze, charcoal) in sunny climates

Choose Vinyl If:

✅ Tight budget requiring lowest initial cost

✅ Inland location (>10 miles from coast) with moderate climate

✅ Traditional architecture (colonial, craftsman) where thicker frames appropriate

✅ Cold climate (Zone 6-8) where insulation maximization critical

✅ Short-term ownership (<10 years) where replacement won’t be your problem

✅ Light colors only (white, beige, tan) in residential setting

The Hybrid Approach (Best of Both Worlds)

For mixed-risk properties:

- Front of house + visible windows: Aluminum (curb appeal, longevity)

- Back/side windows: Vinyl (cost savings on low-visibility areas)

For multi-story buildings:

- Ground-4th floor: Aluminum (security, weather exposure)

- 5th floor+: Vinyl (lower risk, adequate performance)

Vinyl vs. Aluminum Windows (FAQs)

Can I paint vinyl windows to change the color?

- Adhere poorly (peeling/chipping over time)

- Trap heat, especially with dark colors, increasing the risk of warping/bowing

- Potentially void the manufacturer warranty

Do aluminum windows sweat or get icy in winter?

Modern thermal-break aluminum uses an insulating polyamide strip to separate interior and exterior metal. When properly designed, it can perform close to quality vinyl for condensation resistance.

When shopping, ask: “Is it thermally broken, and how wide is the thermal break?” In colder climates, very small breaks (often under ~14 mm) are commonly insufficient compared to wider thermal-break designs.

Will vinyl windows increase my home value?

- You’re replacing old wood or single-pane windows (comfort + energy savings)

- You’re in a market where vinyl is the “normal” expectation

- Your existing windows are visibly worn, fogged, or damaged

- You’re in coastal or harsh-exposure areas where durability is a buyer focus

- The home is modern/luxury where aluminum is perceived as a premium material

- It’s a commercial/multi-family property where long-term operating cost matters

What’s the lead time difference between vinyl and aluminum windows?

- Standard projects (20–40 windows): Vinyl 3–6 weeks; thermal-break aluminum 6–8 weeks

- Custom/large projects (50+ windows, custom colors): Vinyl 6–10 weeks; aluminum 8–12 weeks

Why Hotian for Your Aluminum or Vinyl Project

We manufacture both materials because we know there’s no universal “best”—the right choice depends on your building’s climate zone, architectural style, budget, and ownership timeline.

Our Manufacturing Advantages

Thermal-Break Aluminum Systems

- 24mm polyamide thermal break standard (not 14mm economy grade)

- AAMA 2605 powder coating (40-year fade resistance)

- Miami-Dade NOA certified impact-rated options for hurricane zones

- U-factor down to 0.30 with appropriate glazing (matches vinyl performance)

- Custom RAL color matching available

Commercial-Grade Vinyl Systems

- Multi-chamber profiles with foam insulation options

- Fusion-welded corners (no mechanical fasteners) for watertight frames

- Stainless steel hardware (coastal upgrade available)

- U-factor 0.26-0.30 depending on configuration

- 20-year+ transferable warranty options (frame & hardware)

Project Support (20+ Window Orders)

- Factory-direct pricing (eliminate distributor markup)

- Submittal packages (CAD details, test reports, specifications)

- Installation training for your crew (on-site or virtual)

- Volume discounts: typically 15-25% off for 50+ units

💡 Pro Tip for Large Projects:

Schedule a factory tour (virtual or in-person) during design development. See the thermal break assembly process, quality control testing, and material handling. Understanding manufacturing clarifies which features matter vs which are marketing. We host dozens of project teams annually—most say it’s the most useful hour of their spec research.

Take Action: Next Steps by User Type

🏠 For Homeowners

Immediate actions:

- Determine your climate exposure (5 min):

- Check climate zone: ENERGY STAR Zone Map

- Measure distance to coast: Google Maps

- Result: Narrows material choice to 1–2 realistic options.

- Calculate lifetime cost (10 min):

- Use the 50-year TCO table above.

- Factor in: How long you plan to own the home.

- Result: Understand total investment, not just sticker price.

- Get comparison quotes (this week):

- Request quotes for both materials (don’t pre-decide).

- Ensure aluminum quotes include thermal break specs.

- Compare: Initial cost, warranty, U-factor, lifespan.

Browse aluminum window catalog →

Browse vinyl window catalog →

🏗️ For Contractors & Builders

Project planning actions:

- Download specification templates (today):

- Aluminum: CAD details, ASTM test reports, submittal sheets.

- Vinyl: Energy compliance data, installation standards.

- Request volume pricing (this week):

- 20+ windows: target 15-18% discount.

- 50+ windows: 20-25% discount + free submittal prep.

- 100+ windows: Custom pricing + on-site training.

- Schedule material consultation (design phase):

- Review: Building location, architectural style, budget targets.

- Receive: Optimized material recommendation by opening.

- Timeline: 1-hour call or on-site meeting