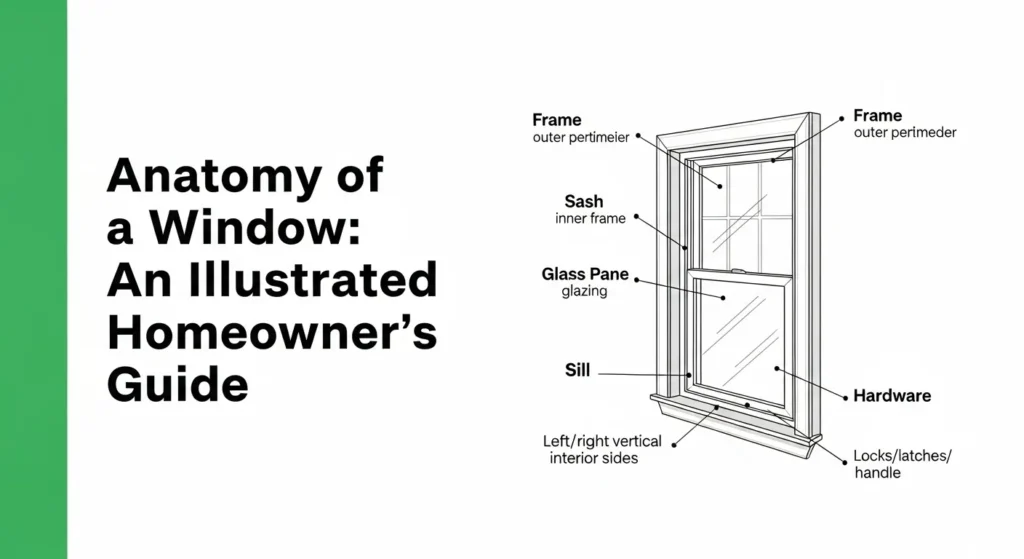

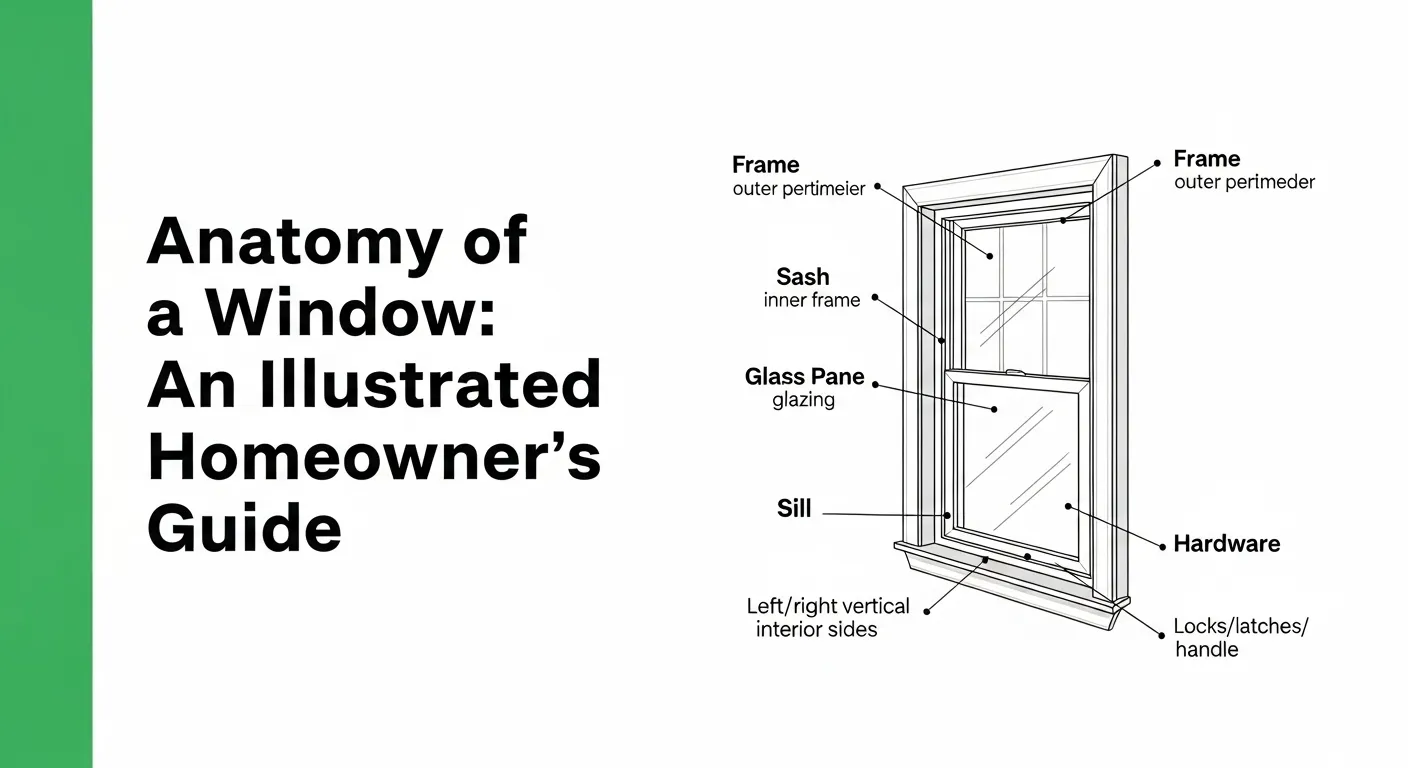

Understanding window anatomy helps you choose better products, maintain energy efficiency, and diagnose issues before they become costly repairs. Inspired by the clarity found in Pella-style diagrams, this guide defines each part and shows how the pieces work together as a sealed system for structure, comfort, security, and performance.

A window is a system composed of the frame (stationary), sash (moving frame that holds glass), glazing (glass and its insulated layers), hardware, seals, and exterior/interior trim.

When these parts are specified and installed correctly, you get quieter rooms, lower energy bills, smoother operation, and longer service life.

Explore related design choices in Vertical vs. Horizontal Windows and style options in Window Trim Styles. If you need help selecting or sizing, see our custom solutions: custom windows from us.

Interactive Window Diagram: Explore the Anatomy

Answer first: Use this labeled diagram to learn each component’s name and function. Hover to see a one-sentence definition; click to jump to the detailed section.

Interactive Window Diagram

Click or tap on any labeled point to learn more about each component

? Tip

Click any labeled component to see detailed information

Window Components

Select a component from the diagram to learn more about its function and purpose in the window assembly.

Interactive Window Diagram – Click any component to learn more

Labels and quick functions:

- Head — Top horizontal frame member that sheds water and supports the opening. → See Head

- Jambs — Vertical frame members that guide the sash and house balances. → See Jambs

- Sill — Exterior bottom frame, sloped to drain water away. → See Sill

- Stool — Interior ledge at the bottom inside the room. → See Stool

- Casing (Trim) — Interior/exterior molding that covers the gap to the wall. → See Casing & Trim

- Sash — Movable frame holding the glazing (glass). → See The Window Sash

- Rails — Horizontal members of the sash (meeting rail at the center). → See Rails & Stiles

- Stiles — Vertical members of the sash that interface with jambs. → See Rails & Stiles

- Glazing — The insulated glass system (panes, spacers, gas, coatings). → See Glazing Technology

- Grilles — Decorative bars that simulate divided lites. → See Grilles & Mullions

- Lock — Hardware that secures the operable sash. → See Lock & Lift

- Lift — Handle or finger pull for raising/lowering the sash. → See Lock & Lift

- Weatherstripping — Seals that block air/water around sash/frame. → See Weatherstripping

- Balances — Hidden counterbalances that hold sash position. → See Balances

Tip: For multi-unit openings, mullions connect frames; see Grilles & Mullions.

What Is the Window Frame and What Are Its Parts?

Answer first: The window frame is the stationary perimeter—head, jambs, and sill—that supports the sash, anchors to the wall, sheds water, and provides channels for operation and weather seals.

- Typical frame materials: vinyl, wood, fiberglass, aluminum

- Critical performance roles: structural support, water management, air sealing, anchorage for hardware

Head: How Does the Head Protect Against Water?

The head is the top horizontal frame member. It must direct water away from the opening and support the sash tracks or hinges.

- Best practice: integrate head flashing/drip cap behind cladding to shed water over the exterior trim.

- Info gain: In rain-exposed walls, a 10-degree or greater drip cap slope with end dams reduces water intrusion.

Jambs: What Do Jambs Do Besides “Hold the Sash”?

Jambs are the vertical frame members that guide the sash and house balances (for hung windows) or hinges/operating hardware (for casements/awnings).

- Interior features: balance wells, weatherstrip contact surfaces

- Exterior features: weep paths (vinyl/aluminum), accessory grooves for trim

- Tolerance matters: even 1/16" bow can cause binding or air leakage

Sill: Why Is the Sill Sloped?

The sill is the exterior bottom frame member, typically sloped 8–15 degrees to shed water beyond the cladding.

- Drainage: look for weep holes/slots; keep them clear to prevent interior leaks

- Thermal: thermally broken sills reduce condensation risk in cold climates

Stool: What Is the Interior “Shelf” at the Bottom?

The stool (often called a “sill” indoors) is the interior ledge. It’s not structural, but it finishes the interior and covers the frame-to-drywall gap.

- Pair with an apron below for a finished look

- Material: wood or composite; seal edges to prevent paint cracking

Casing & Trim: What Covers the Gap to the Wall?

Casing and trim (interior and exterior) bridge between the frame and the wall, hiding insulation/foam and fasteners and keeping the assembly weathertight.

- Exterior: brick mould or integrated cladding; back-caulk with high-quality sealant

- Interior: head casing, side casings, stool and apron

- Explore profiles and looks in Window Trim Styles

- Troubleshooting: Aluminum vs. Vinyl Windows

- Maintenance: Wood vs. Vinyl Windows

- Installation: Fiberglass vs. Vinyl Windows

What Is the Window Sash and How Does It Work?

The sash is the moving (or fixed) inner frame that holds the glass and interfaces with weatherstripping and locks to create a tight, operable seal.

- Types by operation: single-hung, double-hung, casement, awning, slider, picture (fixed)

- For operation trade-offs, see Single-Hung vs. Casement vs. Picture vs. Sliding Windows and Single-Hung vs. Double-Hung Windows

Rails & Stiles: What’s Their Job?

Rails (horizontal) and stiles (vertical) form the sash perimeter.

- Meeting rail: where upper/lower sashes meet; critical for lock alignment and air seal

- Reinforcements: fiberglass/steel inserts (vinyl) for rigidity and reduced deflection

- Sightlines: slimmer rails/stiles increase daylight but must balance stiffness

Weatherstripping: Why Is It So Critical?

Weatherstripping lines the contact points between sash and frame to block air and water.

- Common types: bulb, fin-seal, compression, and magnetic (on some steel doors/windows)

- Performance tip: Replace brittle, flattened, or torn strips to reduce drafts 10–25%

- Maintenance: clean debris from tracks; silicone-safe lubricant on contact points (avoid petroleum on vinyl)

See Cleaning and Maintaining Vinyl Windows for step-by-step care.

Hardware: How Do Lock & Lift Components Improve Performance?

Locks pull the sash tight to compress weatherstripping; lifts/pulls enable smooth operation.

- Hung windows: cam or auto-locks at meeting rail; lifts on lower rail

- Casements/awnings: multipoint locks and crank operators increase air/water tightness

- Security: laminated glass and multipoint locks increase forced-entry resistance

What Is Glazing and How Does It Affect Efficiency?

Glazing is the entire glass system—panes, spacers, gas fills, and coatings. It governs heat flow, solar gain, condensation resistance, and noise control.

- Key metrics: U-Factor (heat loss), SHGC (solar heat), VT (visible light), CR (condensation resistance), and optional STC (sound)

- Learn the basics: what is U-Factor

Pane Layers: Single vs. Double vs. Triple

- Single-pane: minimal insulation; not recommended for exterior use

- Double-pane (IGU): today’s baseline; U-Factor roughly 0.28–0.35 with Low‑E and argon

- Triple-pane: best for cold/noisy zones; U-Factor ~0.16–0.22; slightly lower VT

Note: NFRC-labeled products provide certified performance values.

Spacers: Why “Warm-Edge” Matters

Spacers separate panes and reduce conductive heat flow.

- Types: aluminum (cold edge), stainless, silicone foam, composite “warm-edge”

- Benefit: warm-edge spacers increase edge-of-glass temperatures, cutting condensation risk and improving CR scores

Gas Fills: Argon vs. Krypton

- Argon: cost-effective, optimal at ~1/2" pane gaps (double-pane)

- Krypton: better in narrow gaps (~3/8"), common in triple-pane IGUs

- Longevity: modern IGUs use dual seals (PIB primary + silicone/urethane secondary) to limit gas loss over decades

Low‑E Coatings & Tints: Invisible Energy Control

- Soft-coat (sputtered) Low‑E: highest performance; commonly used inside IGUs

- Hard-coat (pyrolytic) Low‑E: durable, slightly higher emissivity

- Tuning:

- Cold climates: low U‑Factor, moderate SHGC to capture winter sun

- Hot climates: low SHGC to block summer gain

- Tints: reduce glare/heat; can lower VT; select carefully for daylighting goals

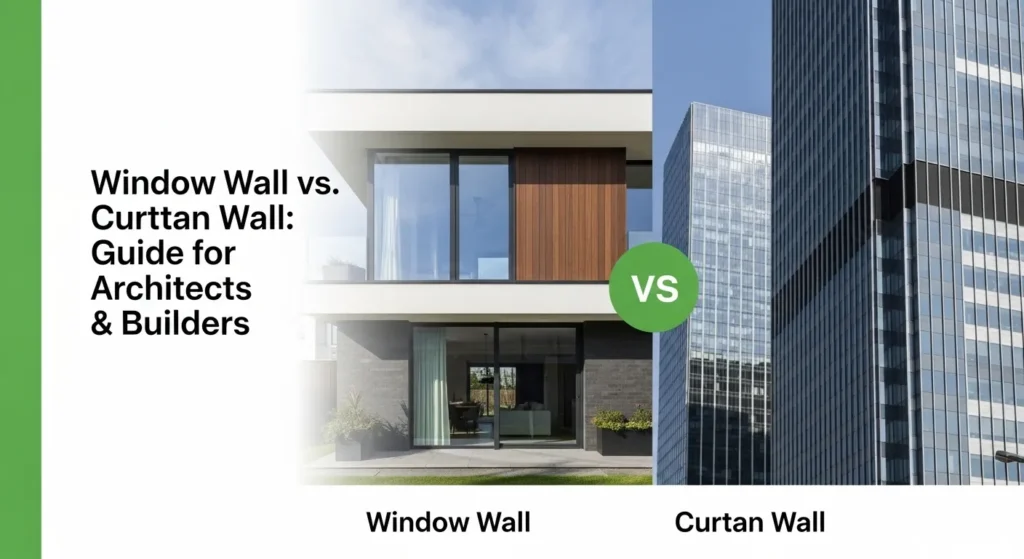

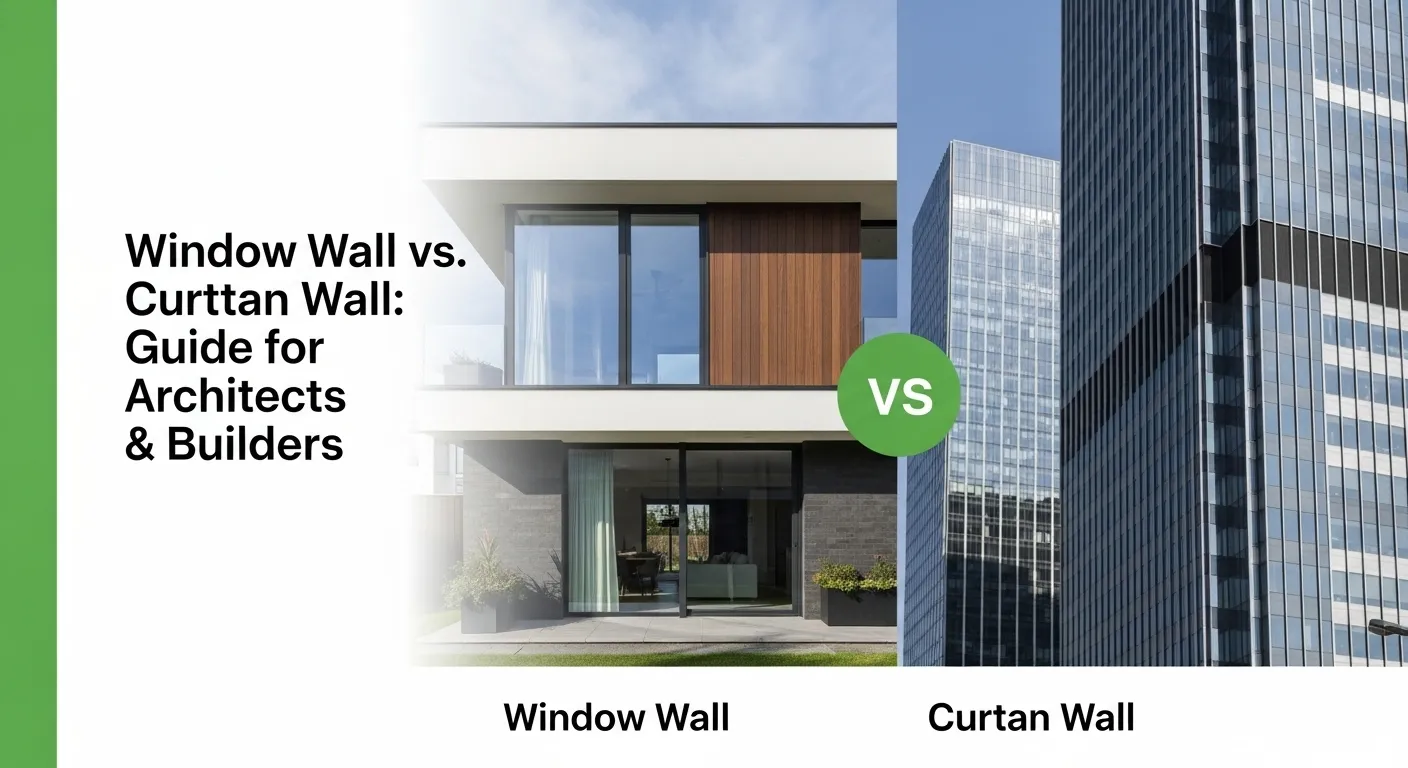

For large glazed openings, compare systems: window-wall vs. curtain-wall.

Hardware & Accessories: What Else Makes Windows Work?

Hidden mechanisms and add-ons—balances, grilles, mullions—impact ease of use, safety, style, and multi-unit configurations.

Balances: How Do Sashes Stay Put?

Balances counteract sash weight so it opens easily and stays where you leave it.

- Types:

- Spiral: simple, periodic tensioning required

- Block-and-tackle: smooth, durable for heavier sashes

- Constant-force (coil): compact, consistent force, low maintenance

- Symptom mapping:

- Won’t stay open? Balance fatigue/failure

- Slams shut? Broken or unhooked balance

- Jerky motion? Dirty tracks or damaged shoes

Grilles & Mullions: Style vs. Structure

- Grilles (muntins): decorative simulated divided lites (SDL on surface, GBG inside glass, or removable interior grilles)

- Mullions/mull posts: structural members that join multiple window units into one opening

- Authenticity: “true divided lites” use individual panes—higher cost, lower efficiency than IGUs with grilles

FAQ below clarifies grilles vs. true divided lites.

Which Window Frame Material Is Best? (Side-by-Side Comparison)

Vinyl offers low cost/maintenance; fiberglass balances durability and thermal performance; wood is premium and insulates well but needs care; aluminum is strongest and slim but least insulating unless thermally broken.

| Material | Durability | Maintenance | Insulation (typical U-Factor) | Relative Cost | Notes |

|---|---|---|---|---|---|

| Vinyl (uPVC) | Good | Low | 0.26–0.35 (double, Low‑E, argon) | $450–$800 | May expand/contract; choose reinforced frames for large sizes |

| Fiberglass | Excellent | Low | 0.20–0.30 (double/triple) | $500–$1,000 | Stable, paintable, high strength-to-weight |

| Wood (clad) | Very good (with cladding) | Moderate | 0.22–0.30 | $600–$1,500+ | Warm aesthetics; needs interior sealing; exterior cladding recommended |

| Aluminum (thermally broken) | Excellent | Low | 0.35–0.50 (improves with triple/thermal breaks) | $400–$850+ | Slim sightlines; best in warm climates or commercial-grade units |

How Do You Maintain Windows and Troubleshoot Problems?

Clean tracks and sweeps, inspect seals annually, lubricate moving parts with manufacturer-approved products, and address small issues early to preserve energy performance and smooth operation.

Routine Care (Annual/Biannual)

- Clean tracks and weep holes; vacuum debris and flush gently with water

- Inspect weatherstripping; replace flattened or torn segments

- Check glazing seals for fogging; inspect exterior sealant joints

- Lubricate balances, locks, and rollers (use silicone/PTFE on vinyl/fiberglass)

- Repaint/refinish exposed wood; reseal end-grain and joints

Common Problems & Likely Culprits

- Drafts or whistle? Weatherstripping wear, misaligned lock/keeper, out-of-square frame

- Sash won’t stay up? Fatigued or broken balances

- Hard to open/close? Dirty tracks, warped sash, swollen wood, mis-set hinges/rollers

- Fogging between panes? IGU perimeter seal failure (replace IGU)

- Water on interior stool? Clogged weeps, failed exterior sealant or flashing

Concerned about outside noise? Explore soundproof window costs and performance upgrades (laminated glass, triple-pane, wider air spaces, and compression-seal casements).

How Do You Choose the Right Parts for Your Home?

Match glazing to climate, material to maintenance and aesthetics, and operation to room function; prioritize performance metrics (U‑Factor, SHGC, CR, and STC if noise matters).

Climate-Based Recommendations

- Cold climates:

- Triple-pane with argon or krypton; U‑Factor ≤ 0.22

- Moderate SHGC (0.35–0.55) on south-facing windows for passive solar

- Hot/sunny climates:

- Double or triple-pane with low SHGC (≤ 0.25), spectrally selective Low‑E

- Consider tints only if glare control is needed

- Mixed climates:

- Double-pane, low U‑Factor (≤ 0.28), balanced SHGC (0.25–0.40)

Architectural Style Fit

- Traditional: wood/clad frames, colonial or prairie grille patterns

- Modern/minimal: fiberglass or thermally broken aluminum, no grilles, narrow sightlines

- Match openings and proportions using Vertical vs. horizontal windows.

- Coordinate with interior/exterior trim in window trim styles.

Performance Priorities

- Noise reduction: laminated glass, triple-pane, casement/awning compression seals

- Security: laminated glass + multipoint locks

- Ease of cleaning: tilt-in double-hung or inward-opening casements

- Ventilation: casement/awning (catch breezes), sliders for wide openings

- Operation choice guides:

For specialty sizes or unique finishes, explore custom windows from us.