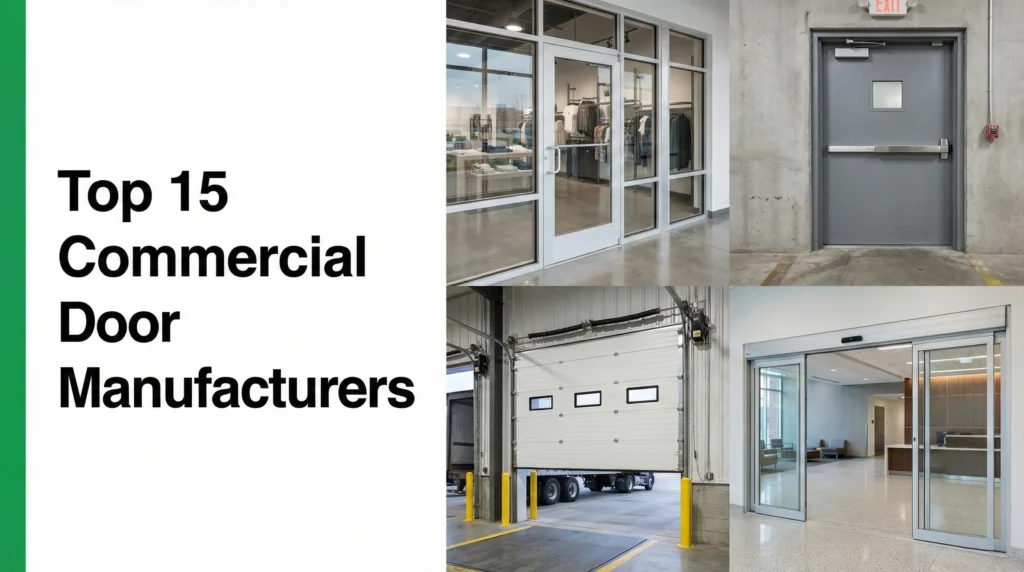

Hurricane impact windows use a Design Pressure (DP) rating そして Missile Impact Level to measure storm resistance. In 2026, homeowners should focus on DP 50+ for standard coastal zones そして DP 70+ for high-velocity hurricane zones (HVHZ). The main change is moving from regular PVB laminate to SGP (SentryGlas Plus) layers that can handle impacts five times stronger without bending—important for storms that last several days

If you’re in Florida, Texas, or any coastal zone, understanding these ratings directly impacts insurance premiums (up to 20-50% discounts), building code compliance, and whether your windows survive the next Category 5 storm without turning your home into a wind tunnel.

Why 2026 Is the Critical Year for Impact Window Decisions

1. Insurance Crisis Drives Urgency

Florida and Texas homeowners face skyrocketing insurance premiums in 2025-2026. Insurance carriers now mandate specific impact ratings before offering wind coverage or discounts. Without proper certification, you may be uninsurable or face $8,000-$15,000 annual premiums.

Real Data: Homes with HVHZ-rated impact windows in Miami-Dade County save an average of $3,200 annually on wind mitigation credits.

2. Building Code Updates (The 25% Rule)

Florida Building Code’s “25% Rule” states: If you replace more than 25% of your windows, the entire home must be upgraded to current hurricane standards. Many homeowners discover this mid-project, turning a $10,000 window replacement into a $40,000+ forced compliance upgrade.

重要なポイント: Plan whole-house upgrades upfront, or strategically replace 24% of windows per phase to avoid triggering full code compliance.

3. Technology Leap: SGP Interlayers

2026 marks the mainstream adoption of SGP (SentryGlas Plus) laminate technology. Unlike traditional PVB (polyvinyl butyral) that softens and sags after impact, SGP remains rigid like a steel plate even after glass shatters—maintaining structural integrity for days during extended storm events.

Decoding the Numbers: What Ratings Actually Mean

Design Pressure (DP) Rating: The Wind Strength Metric

Common Misconception: “DP 50 means it resists 50 mph winds.”

Reality: DP 50 means it resists 50 pounds per square foot (psf) of pressure—equivalent to approximately 170+ mph sustained winds.

| DP Rating | Pressure Resistance | Wind Speed Equivalent | Recommended Zones |

|---|---|---|---|

| DP 30 | 30 psf | ~140 mph | Inland areas, low-risk zones |

| DP 50 | 50 psf | ~170 mph | Standard coastal residential |

| DP 70 | 70 psf | ~200 mph | HVHZ (Miami-Dade, Broward) |

| DP 100+ | 100+ psf | 230+ mph | Oceanfront high-rises, Cat 5 zones |

プロのヒント: Don’t buy DP 70 windows if you’re 30 miles inland in Orlando—you’re overpaying by 30-40%. Match your rating to your actual wind zone, determined by ASCE 7-22 maps (not just “coastal” vs “inland”).

Missile Impact Levels: What Flies at Your Windows

Impact windows must survive standardized projectile tests. The two levels correspond to building height and debris risk:

Large Missile (Level D)

- Test: A 9-pound 2×4 wooden stud fired at 50 feet per second

- Who Needs It: Buildings under 30 feet (typically 1-2 story homes)

- なぜ: Ground-level structures face flying lumber, tree branches, and construction debris during storms

Small Missile (Level A)

- Test: 10 ball bearings (2 grams each) fired at 130 feet per second

- Who Needs It: Buildings over 30 feet (3+ story buildings, high-rises)

- なぜ: Upper floors face wind-driven gravel and small debris, not heavy lumber

Money-Saving Insight: If you live on the 15th floor of a Miami condo, don’t pay for Level D certification—you only need Level A. This can save $150-$300 per window unit.

The Three-Layer Defense System: How Impact Windows Actually Work

Layer 1: The Frame (Structural Anchor)

2026’s market offers three primary frame materials, each with distinct advantages:

| 材料 | 強さ | 最適な用途 | 寿命 | 料金 | Hotian Prices |

|---|---|---|---|---|---|

| 熱分解アルミニウム Alloy | ⭐⭐⭐⭐⭐ | Coastal HVHZ, high-rises | 30年以上 | $80 – $140 / sq. ft. ($900 – $2,500 per unit) | $110-$150+ |

| Reinforced uPVC (Vinyl) | ⭐⭐⭐⭐ | Standard residential, inland | 20~25歳 | $40 – $75 / sq. ft. ($400 – $800 per unit) | $60-$90+ |

| Steel/Iron | ⭐⭐⭐⭐⭐ | Historic retrofit, security | 40年以上 | $150 – $350+ / sq. ft. ($2,500 – $5,000+ per unit) | $98-$120+ |

Hotian Specialization: We manufacture all three frame types with custom reinforcement schedules:

- アルミニウム: Multi-chamber profiles with thermal breaks for energy efficiency

- ポリ塩化ビニル: Steel-reinforced core for DP 50-70 certification without aluminum’s cost

- 鋼鉄: Powder-coated corrosion-resistant systems for coastal salt environments

Layer 2: The Glass & Interlayer (Impact Absorption)

This is where 2026’s technology revolution happens:

PVB (Traditional Standard)

- 仕組み: Soft plastic layer sandwiched between two glass panes

- Behavior: Glass shatters but remains stuck to the sticky PVB film

- Weakness: Prolonged exposure (12+ hours) causes PVB to sag like wet cloth, potentially creating openings

- 料金: Baseline pricing

SGP (SentryGlas Plus) – 2026 Premium Standard

- 仕組み: Ionic polymer interlayer 100× stiffer than PVB

- Behavior: Even after glass shatters, the SGP layer remains rigid like a plywood board

- アドバンテージ: Can withstand 5× higher impact forces and remains structurally intact for days

- 料金: 20-35% premium over PVB

- 最適な用途: First-row oceanfront, Category 5 zones, multi-day storm events

2026 Recommendation: If you’re in a mandatory evacuation zone (Zone A/B), specify SGP. The price difference ($800-$1,500 per opening) is negligible compared to the total loss during a prolonged Cat 5 landfall.

Layer 3: Hardware & Seals (Pressure Equalization)

Often overlooked, but critical:

- マルチポイントロックシステム: Distribute wind load across the entire frame perimeter

- Compression gaskets: Prevent water intrusion under 8+ inches/hour rainfall rates

- Drainage weep systems: Channel trapped water outward, preventing frame corrosion

Hotian Standard: All our impact systems include stainless steel multi-point locks and EPDM compression seals rated for 200+ mph wind-driven rain.

Certification Maze: What Letters Matter

HVHZ (High Velocity Hurricane Zone)

- カバレッジ: Miami-Dade and Broward counties (Florida’s strictest standard)

- Requirement: Must pass Miami-Dade NOA (Notice of Acceptance) protocol

- Test Includes: Large missile impact + 9,000 pressure cycles simulating hours of wind

- Cost Premium: 25-40% over standard impact windows

- Do You Need It?: Only if you’re in Miami-Dade/Broward or your insurance specifically requires it

Florida Product Approval (FL #)

- カバレッジ: All of Florida outside Miami-Dade/Broward

- Requirement: Pass ASTM E1996 (cyclic pressure) + E1886 (missile impact)

- Verification: Look for “FL#” number on the product label

- 料金: Standard impact window pricing

Texas Department of Insurance (TDI)

- カバレッジ: Texas coastal counties

- Requirement: Similar to Florida but with Texas-specific wind maps

- 利点: Qualifies for Texas Windstorm Insurance Association (TWIA) coverage

Critical: Generic “impact-resistant” labels mean nothing. Always verify:

- Actual DP rating (printed on NFRC label)

- State-specific certification number (FL#, TDI#, NOA#)

- Test reports from accredited labs (not manufacturer claims)

ROI Calculator: When Do Impact Windows Pay for Themselves?

Upfront Investment (2026 National Averages)

- Standard Impact (DP 50, PVB): $850-$1,200 per window installed

- HVHZ Rated (DP 70, SGP): $1,400-$2,200 per window installed

- Whole-house (2,500 sq ft home, 20 openings): $25,000-$45,000

Annual Returns

| Benefit Category | Annual Value | Payback Contribution |

|---|---|---|

| Insurance Premium Reduction | $2,000-$4,500 | 7-12 years |

| エネルギー節約 (Low-E glazing) | $400-$800 | 20年以上 |

| Property Value Increase | 5-8% appreciation | Immediate at resale |

| Storm Damage Avoidance | $15,000-$50,000 (one event) | Priceless |

Real Example: A Sarasota homeowner installed $38,000 in impact windows in 2023. During Hurricane Idalia (2023) and Hurricane Debby (2024), neighbors had $22,000 and $18,000 in wind/water damage respectively. The homeowner: $0 damage, $3,600 annual insurance savings, 5.2-year effective payback.

The Hidden Benefits No One Talks About

1. Burglary Deterrence

Impact windows are nearly impossible to breach quickly. Laminated glass resists repeated sledgehammer blows—a burglar would need 5-10 minutes of loud hammering to create an entry point. This makes them superior to security bars without the prison aesthetic.

Market Data: Homes with impact windows see 82% fewer break-in attempts in South Florida crime studies.

2. Sound Insulation

The laminated construction blocks 95% of exterior noise. If you live near airports, highways, or urban centers, impact windows deliver premium acoustic performance as a free bonus.

Unexpected Market: Tokyo and Hong Kong high-rises now specify “disaster-grade laminated glass” primarily for noise reduction, with typhoon resistance as secondary benefit.

3. UV Protection

SGP interlayers block 99% of UV radiation, protecting flooring, furniture, and artwork from sun damage—particularly valuable in Florida’s intense sun.

Regional Considerations: One Size Doesn’t Fit All

Florida Specifics

- The Insurance Trigger: State Farm, Citizens, and major carriers often require full HVHZ for coastal policies

- Salt Corrosion: Specify marine-grade hardware and aluminum anodizing (not just powder coat)

- Code Enforcement: County inspectors will red-tag non-compliant installations—verify installer licensing

Texas Gulf Coast

- TWIA Requirements: Must have TDI certification for windstorm coverage

- Hail Consideration: Many Texas zones face both hurricanes and hailstorms—consider Class 4 impact-resistant roofing coordination

Caribbean & International

- Certification Gaps: Many islands lack local standards—reference ASTM E1996/E1886 as baseline, specify Miami-Dade NOA for premium protection

- Shipping Logistics: Custom sizes require 8-12 week lead times—plan projects around hurricane season gaps

The 2026 Buying Checklist

Before You Sign a Contract

✅ Verify Actual Certifications

- Request physical NOA, FL#, or TDI documentation (not just contractor claims)

- Cross-check certification numbers on official databases

✅ Match Rating to Risk

- Use NOAA wind zone maps (not just “we’re coastal”)

- Don’t over-specify: DP 70 inland Orlando is wasted money

✅ Specify Interlayer Type

- PVB: Acceptable for standard residential

- SGP: Mandatory for oceanfront, HVHZ, or Cat 5 zones

✅ Frame Material Selection

- アルミニウム: Best structural performance, coastal durability

- Reinforced uPVC: Cost-effective for inland/low-rise

- 鋼鉄: Historic buildings, maximum security needs

✅ Installation Matters More Than Product

- Verify installer holds FL Building Code Administrator license (or state equivalent)

- Require installation photos documenting anchor spacing, flashing, and sealant

- Get written warranty covering both product AND installation (minimum 10 years)

✅ Energy Performance Integration

- Specify Low-E coating (blocks heat without sacrificing light)

- Request NFRC label showing U-factor and SHGC for your climate zone

- Consider triple-pane for maximum insulation in extreme climates

Common Mistakes That Cost Thousands

❌ Mistake #1: Buying Based on Price Per Window

- Reality: Installation quality determines 50% of performance. A $900 window improperly anchored will fail where a $700 window correctly installed survives.

- Fix: Evaluate total installed cost + installer credentials, not unit price.

❌ Mistake #2: Ignoring the 25% Rule

- Reality: Replacing 8 windows triggers whole-house code compliance in Florida—suddenly you need impact doors, garage door reinforcement, roof attachments.

- Fix: Get a code compliance assessment BEFORE starting any window project.

❌ Mistake #3: Assuming All “Impact” Glass Is Equal

- Reality: Laminated glass for shower doors is not hurricane-rated. “Impact-resistant” ≠ certified impact windows.

- Fix: Only accept products with DP rating + missile level + state certification number on permanent labels.

❌ Mistake #4: Neglecting Long-Term Maintenance

- Reality: Weep holes clog, gaskets degrade, hardware corrodes—neglect voids warranties and reduces lifespan by 40%.

- Fix: Annual inspection and cleaning (especially in salt environments); budget $200-$400/year for professional maintenance.

FAQ: The Questions Every Homeowner Asks

Can I install impact windows myself?

Do impact windows eliminate the need for hurricane shutters?

How long does whole-house impact window installation take?

Will impact windows affect my home’s appearance?

Do I need impact-rated sliding glass doors too?

Can I get impact windows in black or custom colors?

Do impact windows reduce noise and UV?

Do impact windows require maintenance?

Hotian Impact Window Systems: Engineered for Your Project Scale

For Contractors, Developers & Commercial Projects: Source impact windows that meet spec, arrive on schedule, and install without callbacks.

What Sets Hotian Apart

1. Triple Material Platform

We manufacture all three primary frame systems in-house—no outsourcing, no supply chain gaps:

- 熱分解アルミニウム: Multi-chamber profiles, 1.5″ slim sightlines, custom extrusion dies for unique profiles

- Reinforced uPVC: Steel-core reinforcement achieving DP 50-70 without aluminum pricing

- Steel/Iron Systems: Powder-coated marine-grade for coastal and historic applications

2. Certification Flexibility

- Available Certifications: ASTM E1996/E1886, custom DP rating verification (30-100+)

- Optional Upgrades: Miami-Dade NOA coordination, TDI submission support

- ドキュメント: Full test reports, engineer stamped drawings, installation manuals

3. Custom Glazing Configurations

- Interlayer Options: PVB (0.030″-0.090″), SGP (0.090″-1.52mm), acoustic PVB

- 低放射コーティング: Climate-specific SHGC optimization (0.23-0.65 range)

- Pane Structure: Double or triple glazing, argon/krypton fills, warm-edge spacers

4. Project Support That Scales

- Engineering: Load calculations, wind zone verification, custom shop drawings

- Logistics: Container optimization, job-site sequencing, phased delivery

- Training: Installer certification programs, on-site technical support for complex geometries

Typical Project Profile: Multi-Family Coastal Development

シナリオ: 80-unit beachfront condo, Galveston TX

Requirement: TDI-certified DP 60, Large Missile Level D, HOA-approved bronze finish

Hotian Solution:

- フレーム: Thermally broken aluminum, bronze anodized (AAMA 2604)

- グレージング: 1″ Low-E SGP laminate (SHGC 0.28, U-factor 0.29)

- ハードウェア: Stainless steel multi-point locks, marine-grade gaskets

- リードタイム: 8 weeks for first prototypes, 14 weeks for full production

- Delivered Cost: 23% below US manufacturer quotes for equivalent spec

How to Start Your Specification Process

Step 1: Send Your Requirements (48-Hour Quote Turnaround)

Email us with:

- Project location (for wind zone verification)

- Opening schedule (sizes, quantities, operable vs. fixed)

- Target DP rating and certification needs

- Frame material preference (aluminum/uPVC/steel)

- Color/finish requirements

Step 2: Prototype & Approval

- Receive preliminary shop drawings + finish samples

- Order test units for stakeholder review (typical: 2-3 units)

- Optional: Third-party testing coordination for custom DP ratings

Step 3: Production & Delivery

- Finalized shop drawings with anchor details

- Production slot reservation (8-16 week lead time depending on volume)

- Container delivery to job site or distributor

Quality Assurance Every Project

- Factory Inspections: Third-party QC before shipment (available)

- Documentation Package: Test reports, material certs, installation guides, O&M manuals

- 保証: 10-year frame/finish, 5-year insulated glass seal (extendable)

Ready to Spec Your Next Impact Window Project?

For Bulk Orders (10+ units)

📧 Send window schedule + wind zone → Receive quote + spec sheets in 48 hours

For Sample Evaluation

📦 Order 1-2 test units → Delivered in 6-8 weeks with full documentation

For Technical Consultation

📞 Schedule 20-minute spec review call → Optimize frame/glazing/hardware for your climate + budget

今すぐHotianにお問い合わせください

Protect your projects with impact windows engineered for real-world storm performance—manufactured at scale, delivered on time, installed with confidence.

Request Custom Quote →

Download Spec Sheets →

Schedule Engineering Call →

Final Thought: The New Normal

In 2026, impact windows are no longer an “upgrade”—they’re baseline protection in any hurricane-prone region. The question isn’t whether to install them, but how to select the right rating, material, and interlayer for your specific risk profile.

Whether you’re protecting a single-family home in Tampa or outfitting a 200-unit development in Cancún, the principles remain: match DP to wind zone, specify SGP for critical exposure, verify certifications independently, and never compromise on installation quality.

The next Category 5 storm is coming. Your windows are either a vulnerability or a fortress—choose accordingly.