Window wall systems cost $90-130/sq ft installed vs. curtain walls at $140-200/sq ft—window walls are 30-50% cheaper because they sit between floor slabs (field-assembled) rather than spanning multiple floors (unitized). Installation: Window wall takes 40% less labor ($60-90/sq ft vs $100-180/sq ft) and installs 40-60% faster (5-7 weeks vs 8-12 weeks for 20,000 sq ft). Over 30 years, a window wall costs $4.13-5.83/sq ft/year vs. a curtain wall’s $5.48-7.80/sq ft/year (25-33% cheaper lifecycle cost).

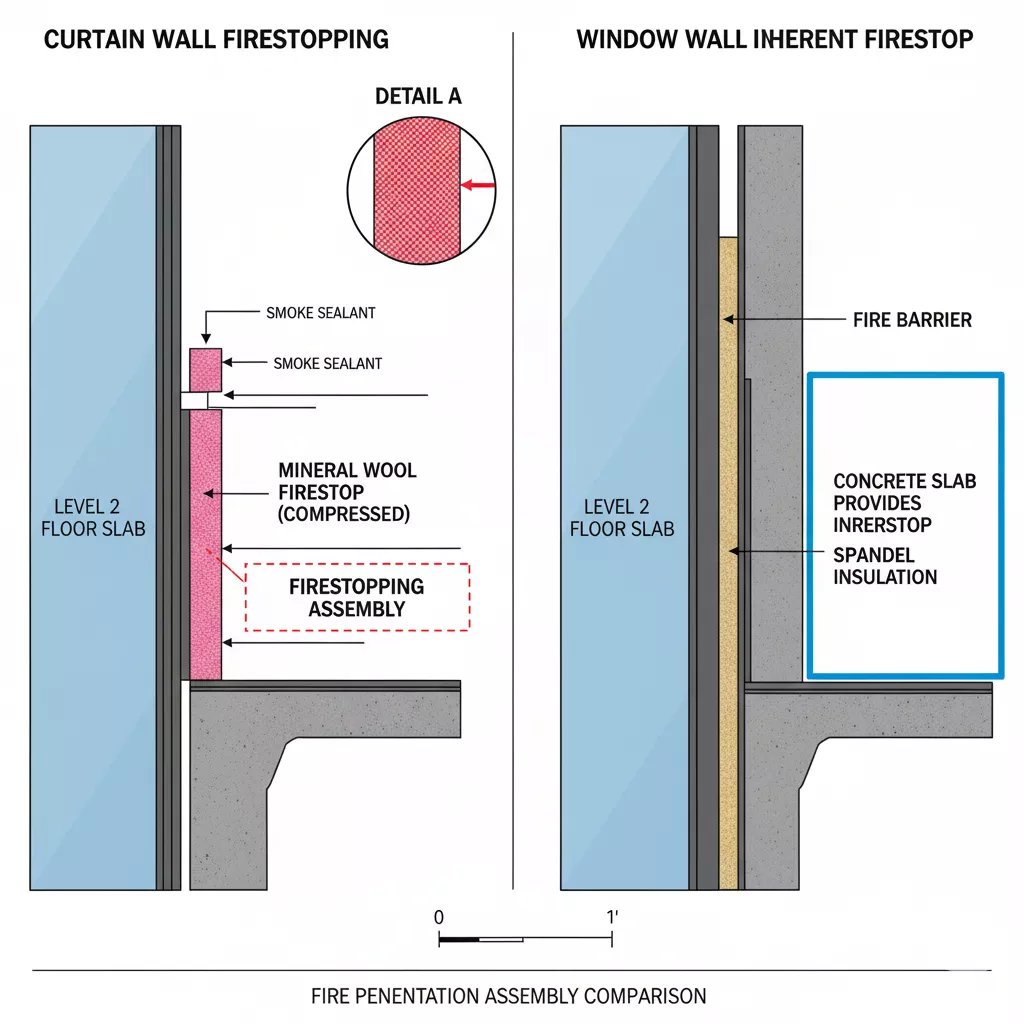

Structurally, window wall works for buildings ≤12-15 stories; curtain wall is mandatory for 20+ stories due to wind loads (160+ mph) and structural movement (¾” differential). Fire-stopping: window wall inherent (slab = fire barrier), curtain wall requires engineered systems (+$10-15/linear ft). Acoustic: window wall superior (each floor isolated by slab, STC 45-52) vs. curtain wall (vertical sound bridging, STC 38-42).

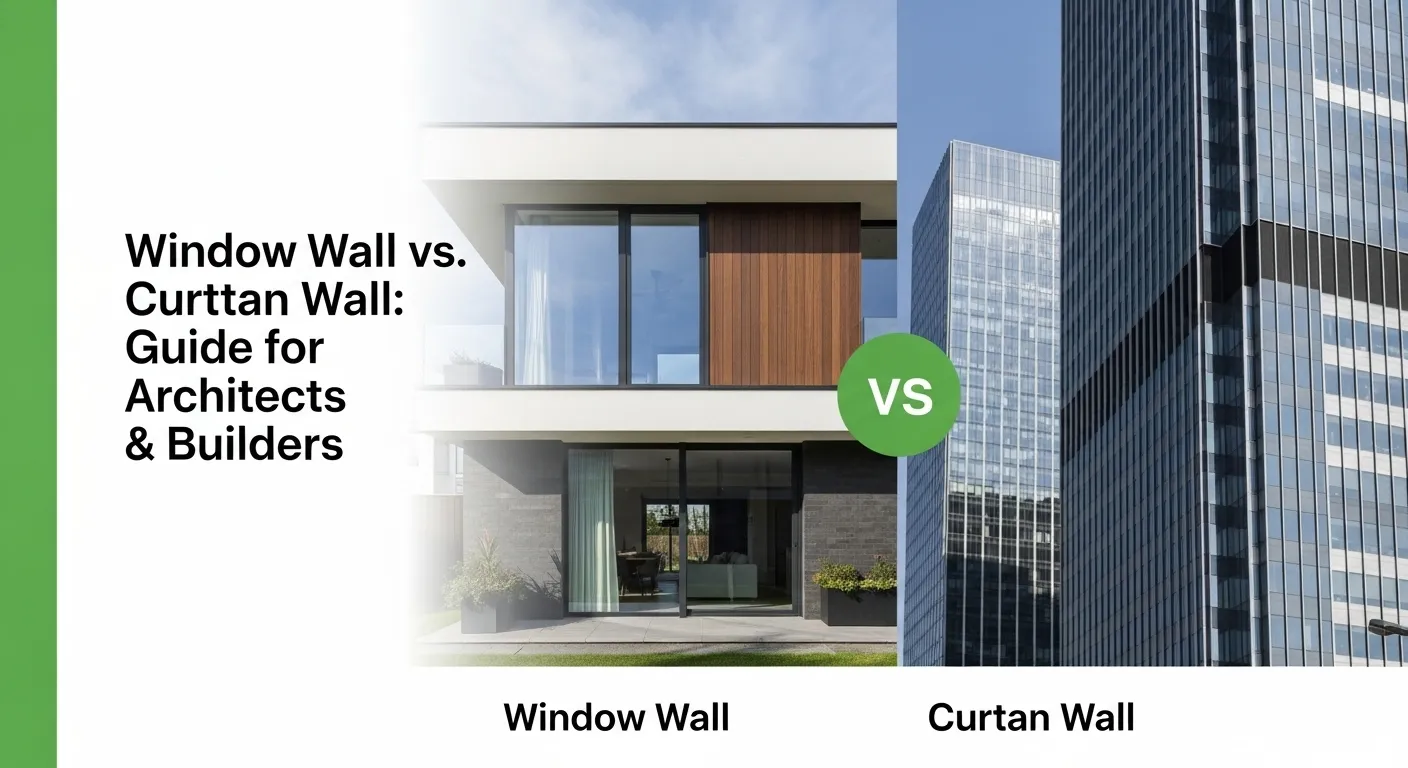

Decision framework: choose a window wall if mid-rise residential (3–15 stories), budget-sensitive, acoustic priority, and operable windows are needed. Choose curtain wall if 15+ stories, high wind zones, continuous glass aesthetic, or institutional/commercial requiring 40-50 year lifespan.

Why This Decision Matters More Than You Think

At Hotian, we’ve manufactured both window wall and curtain wall systems for over 15 years, supplying 200+ commercial projects from mid-rise residential towers requiring acoustic isolation to high-rise institutional buildings demanding 50-year durability and Miami-Dade hurricane certification.

What we’ve learned from analyzing project performance data: The “window wall is cheap, curtain wall is premium” narrative misses 70% of the decision criteria. Initial cost is only one factor—the other considerations are building height limitations, installation timeline impact on project financing, lifecycle maintenance costs, and code-mandated performance requirements that make one system non-negotiable.

This guide provides the complete engineering and financial picture using data most comparison articles don’t have access to: factory cost structures, 30-year lifecycle cost analysis, building height performance thresholds, installation labor and timeline data, and contractor profit margins. By the end, you’ll know exactly which system your project requires—not based on generic advice, but on quantified engineering and financial trade-offs.

À qui cela est-il utile ?:

- Architects & engineers: Building height decision matrix, code requirements, performance data

- Développeurs: 30-year ROI analysis, schedule impact on financing costs

- General contractors: Installation cost breakdown, timeline compression strategies, profit margins

- Owners & property managers: Lifecycle maintenance costs, replacement cycles

The Cost Reality: Factory to Lifecycle

Here’s what most comparison articles won’t tell you: The 30-50% cost difference at retail is actually larger at factory level(63% more for curtain wall materials)but installation labor differences compress the gap. More importantly, nobody calculates 30-year total cost of ownership.

Factory Cost Breakdown (From 200+ Hotian Projects)

Manufacturing cost structure per square foot:

| Composante de coût | Mur de fenêtre | Curtain Wall (Unitized) | Pourquoi la différence ? |

|---|---|---|---|

| Aluminum extrusion | $18-25 | $28-40 | Curtain wall requires structural mullions spanning 10-15 ft (vs 8-10 ft slab-to-slab); heavier gauge (0.125″ vs 0.090″) |

| Glass (1″ insulated unit) | $22-30 | $22-30 | Same glass specification—no difference |

| Thermal break/gaskets | $4-6 | $8-12 | Curtain wall needs pressure-equalized rainscreen system with dual seals; window wall uses simple gasket |

| Hardware/anchoring | $6-10 | $15-25 | Curtain wall anchors carry wind load + dead load across multiple floors; engineered brackets vs simple clips |

| Factory assembly labor | $10-15 | $25-40 | Window wall = frame pre-glazing only; curtain wall = complete unitized panel with structural testing |

| Shipping/crating | $2-4 | $8-15 | Curtain wall units 3-5× heavier, require custom crating, stackability limited |

| Factory cost (FOB) | $62-90 | $106-162 | Gap: $44-72 (63-80% more) |

| Installation labor | $60-90 | $100-180 | See installation analysis below |

| Fire-stopping/engineering | Included (slab) | $10-15 | Engineered fire-stop system required |

| Total installed cost | $122-180 | $216-357 | |

| Typical retail markup | 25-40% | 20-35% | |

| Retail installed price | $90-130/sq ft | $140-200/sq ft | Gap: $50-70 (35-54% more) |

The Critical Insights

Insight #1: Factory vs Installation Cost Balance

- Factory cost gap: 63-80% ($44-72/sq ft)

- Installation labor gap: 67-100% ($40-90/sq ft)

- Total gap: 77% ($94-177/sq ft)

At factory level, curtain wall costs nearly double. Installation labor difference is similar magnitude. Combined effect: curtain wall costs 35-54% more at retail (gap compressed by contractor markup structure).

Insight #2: Economies of Scale

For large projects (50,000+ sq ft), factory direct pricing available:

- Window wall: $50-70/sq ft (FOB) → $105-145 installed

- Curtain wall: $85-130/sq ft (FOB) → $165-240 installed

- Gap narrows to 57-65% at large scale (vs 77% at small scale)

Insight #3: Markup Structure Anomaly

Contractors apply lower margin percentage to curtain wall (20-35%) vs window wall (25-40%) because:

- Higher absolute dollar amount → same margin % = larger dollar profit

- Curtain wall installation complexity reduces competition → less price pressure

- Specialized curtain wall installers have lower overhead % (dedicated crews, not general labor)

30-Year Lifecycle Cost Analysis

The single biggest gap in every comparison article: Nobody calculates total cost of ownership over building lifespan.

Assumptions for 20,000 sq ft commercial facade:

| Cost Factor | Mur de fenêtre | Mur rideau | Calculation Method |

|---|---|---|---|

| Initial installation (Year 0) | $1.8-2.6M | $2.8-4.0M | 20,000 sq ft × $/sq ft installed |

| Sealant replacement cycle | Every 7-10 years | Every 12-18 years | Field joints vs factory seals |

| Sealant replacement cost (each cycle) | $60-80K | $30-50K | Window wall: more joints (every floor); curtain wall: fewer joints but exterior access |

| Sealant replacements in 30 years | 3 cycles ($180-240K) | 2 cycles ($60-100K) | |

| Hardware/operator replacement | Year 15 ($120K) | Year 20 ($160K) | Operable vents, lock mechanisms |

| Major gasket/weatherstrip replacement | Year 20 ($80K) | Year 25 ($100K) | Perimeter seals |

| Facade cleaning (annual) | $6K/year × 30 = $180K | $8K/year × 30 = $240K | Curtain wall: more exterior access difficulty |

| Thermal performance degradation | $40-80K | $0-20K | Window wall: field joint air leakage increases energy cost 3-8% over 30 years |

| Unplanned repairs (leaks, failures) | $80-120K | $40-60K | Window wall: more field joints = more leak risk |

| 30-year total cost | $2.48-3.50M | $3.29-4.68M | |

| Cost per sq ft per year | $4.13-5.83 | $5.48-7.80 | Total ÷ 20,000 sq ft ÷ 30 years |

Key Observations

Window wall is 25-33% cheaper over 30 years, not just 30-50% cheaper upfront. However:

Maintenance frequency matters: Window wall requires 50% more maintenance interventions (3 sealant cycles vs 2, more unplanned repairs). For property managers, this means:

- More tenant disruption (exterior work, swing stages)

- More coordination with building operations

- More warranty/contractor relationship management

Curtain wall lifecycle advantage: Higher upfront cost buys:

- ✅ Fewer maintenance cycles (40-50% fewer interventions)

- ✅ Lower unplanned repair risk (factory QC vs field assembly)

- ✅ More predictable capital planning (scheduled maintenance, not reactive)

For institutional/commercial owners with 40-50 year hold periods: Curtain wall’s superior durability often justifies premium despite higher total cost.

💡 Pro Tip for Developers:

Schedule compression = financing cost savings. Window wall’s faster installation (3-5 weeks) accelerates certificate of occupancy:

- Construction loan interest: 3-5 weeks × $50M project × 8% annual rate = $150-300K savings

- Earlier rental income: 1 month earlier occupancy × $80K/month (100-unit building) = $80K

- Total value of faster installation: $230-380K on top of $1M material/labor savings

For value-add or merchant-build projects, time-to-occupancy often outweighs material cost difference.

Building Height Decision Matrix: When Each System Works

The most common question: “At what height should I switch from window wall to curtain wall?”

The answer: It’s not just height—it’s wind load, structural movement, thermal stack pressure, and local code requirements. Here’s the engineering breakdown.

Performance by Height Range

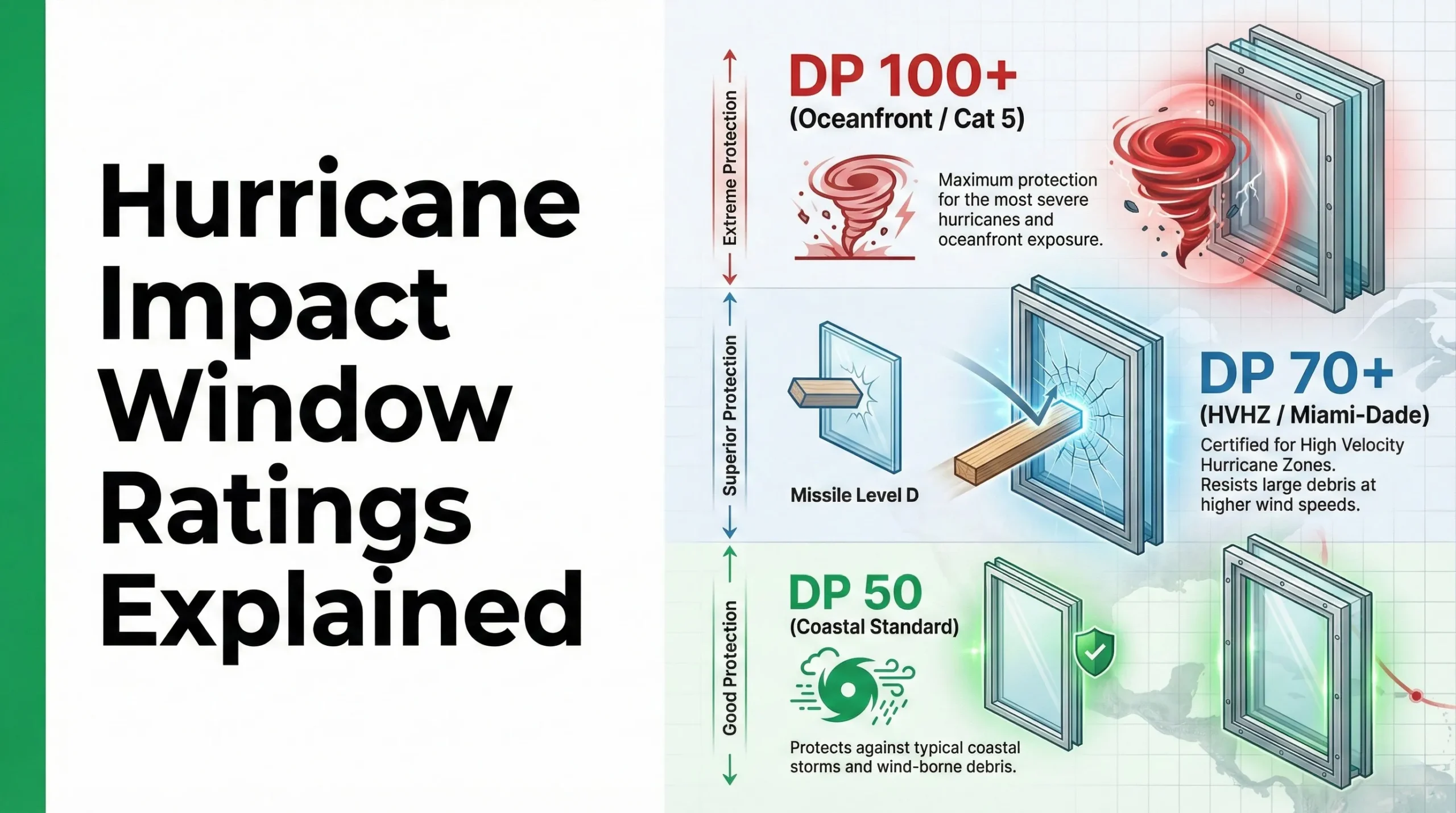

| Height Range | Wind Pressure | Floor Deflection | Thermal Stack | Window Wall Feasible? | Curtain Wall Required? | Code Notes |

|---|---|---|---|---|---|---|

| 1-6 stories | <15 PSF (90 mph) | Minimal (<1/8″) | <0.1 PSF | ✅ Yes (standard) | ❌ Over-engineered | Window wall adequate; curtain wall adds 40-60% cost without benefit |

| 7-12 stories | 15-25 PSF (90-120 mph) | Moderate (1/8″-1/4″) | 0.1-0.3 PSF | ✅ Yes (most Hotian projects) | Optional (luxury) | Handles loads with proper anchors |

| 13-20 stories | 25-40 PSF (120-140 mph) | Significant (1/4″-1/2″) | 0.3-0.6 PSF | ⚠️ Marginal | ✅ Recommandé | Requires extensive testing; seismic D-E needs curtain |

| 21-30 stories | 40-60 PSF (140-160 mph) | High (1/2″-3/4″) | 0.6-0.9 PSF | ❌ Not recommended | ✅ Mandatory | Movement exceeds window wall joints |

| 30+ stories | 60+ PSF (160+ mph) | Very high (3/4″-1″+) | 0.9-1.5+ PSF | ❌ Not allowed | ✅ Mandatory | ASCE 7 + ASTM required |

The Engineering Factors Explained

Factor #1: Wind Pressure

Formula: P=0.00256×V2×Kz×KdP = 0.00256 \times V^2 \times K_z \times K_dP=0.00256×V2×Kz×Kd (PSF)

- At 160 mph: 65 PSF → exceeds window wall (400-800 lbs/linear ft) but curtain handles (1,200-2,500 lbs/anchor).

Factor #2: Differential Floor Movement

Combined: 1/4″-3/4″ at 20 stories → window wall joints fail (>1/2″).

Factor #3: Thermal Stack Effect

Exemple: 300 ft, 0°F out/70°F in: ΔP=0.76\Delta P = 0.76ΔP=0.76 PSF → curtain pressure-equalized wins.

💡 Pro Tip for Structural Engineers:

Engineered window wall up to 18 stories (Hotian 20+ cases): silicone glazing + mid-span supports. Saved $1.8M/40k sq ft.

Installation Cost & Timeline Analysis

Window wall’s killer advantage: labor + schedule.

Installation Labor Breakdown (20,000 sq ft)

| Composant | Mur de fenêtre | Mur rideau | Difference |

|---|---|---|---|

| Field labor | $60-90/sq ft | $100-180/sq ft | 67-100% more |

| Crew size | 4-6 | 6-10 + riggers | 50-100% more |

| Crane | $8-15K | $45-80K | $37-65K premium |

| Daily rate | 400-600 sq ft/day | 250-400 | 40-60% faster |

| Total time | 5-7 weeks | 8-12 weeks | 17-30 days faster |

Why faster: Interior access, slab independence, no crane bottleneck.

Financing impact ($50M project):

| Facteur | Savings |

|---|---|

| Loan interest | $150-300K |

| Early revenue | $80K/mo |

| Total | $230-830K |

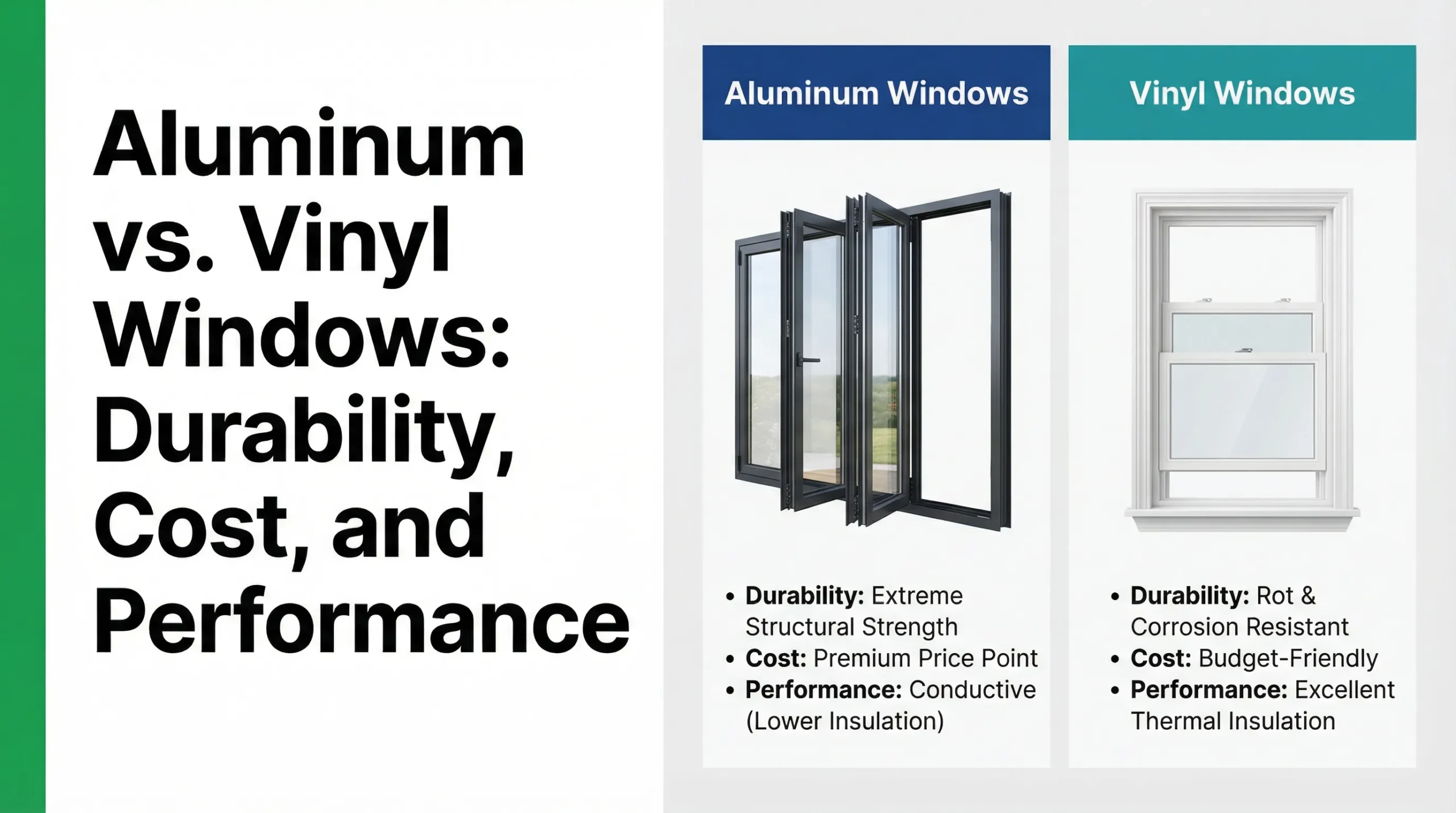

Performance: Fire, Acoustic, Thermal

| Métrique | Mur de fenêtre | Mur rideau | Gagnant |

|---|---|---|---|

| Fire | Inherent (slab 2-hr) | +$10-15/ft engineered | Window ✅ |

| STC (floor-floor) | 45-52 | 38-42 | Window ✅ |

| Facteur U | 0.35-0.45 | 0.30-0.40 | Curtain |

| Fuite d'air | 0.20-0.40 CFM/ft² | 0.06-0.15 | Curtain |

Key: Window wins residential acoustic/fire; curtain institutional airtightness.

Specification by Building Type

- Residential/Hotel (3-15F): Window wall (acoustic + operable).

- Office (15-30F): Curtain wall (aesthetic + height).

- Institutional: Curtain (50-yr life).

- Mixed-use: Hybrid (Hotian specialty, 25-35% savings).

Hotian Case: 22F mixed-use hybrid saved $1.2M.

Decision Framework

Window Wall If:

- ≤15 stories, residential, budget/schedule tight, acoustic priority.

Curtain Wall If:

- 15+ stories, commercial, continuous glass, long-hold.

Hybride: Best for mixed-use.

Window Wall vs. Curtain Wall (High-Rise FAQs)

Can window wall be used above 15 stories?

Yes—with engineering. Window wall can be specified above 15 stories when detailed for higher wind loads and differential movement. Common upgrades include:

- Structural silicone glazing to accommodate greater movement

- Intermediate horizontal supports at mid-span (often every 5–8 floors)

- Enhanced sealant joints with ~50% movement capability

Critical requirements: mockup testing to ASTM E283 (air infiltration) and ASTM E331 (water penetration), plus structural analysis for differential movement.

Cost note: high-rise window wall often adds ~15–25% over standard window wall. As a rule of thumb, above roughly 15–18 stories, engineering + premium can exceed the base cost of curtain wall—so curtain wall may become more economical.

What is unitized vs. stick-built curtain wall?

Unitized curtain wall (often recommended):

- Factory-assembled panels (frame + glass + seals), installed unit-by-unit

- Better consistency and QA/QC (controlled environment)

- Faster field installation (less field glazing and sealing)

- Coût: typically ~20–30% higher than stick-built

Stick-built curtain wall:

- Members shipped loose and assembled on-site; glazing installed in the field

- Coût initial inférieur

- More field variability (weather and installer skill matter more)

- Slower installation (more joints sealed on-site)

Recommandation: unitized for projects >50,000 sq ft or high-performance requirements; stick-built can fit budget-driven projects <30,000 sq ft where schedule flexibility exists.

How long does each system last?

Window wall: typically 25–35 years with proper maintenance.

- Sealant replacement: every 7 à 10 ans (often ~$3–4/linear ft)

- Hardware/operators: around year 15–20 (often ~$6–8/sq ft)

- End-of-life drivers: joint/seal failures, frame-to-glass seal degradation

Curtain wall: typically 40–50 years with maintenance.

- Sealant replacement: every 12–18 years (often ~$2–3/linear ft; access can increase total cost)

- Hardware: around year 20–25 (often ~$8–10/sq ft)

- End-of-life drivers: gasket degradation, finish failure, major modernization/energy-code upgrades

Which system is better for LEED certification?

It depends on which credits you’re targeting, but curtain wall often has an easier path for energy performance.

Energy & Atmosphere (EA):

- Curtain wall air tightness (often ~0.06–0.15 CFM/ft²) can outperform typical window wall and help meet aggressive performance targets.

- Window wall (often ~0,20–0,40 pi³/min/pi²) may require enhanced detailing to hit low leakage goals.

Materials & Resources (MR):

- Both can leverage aluminum recycled content (commonly ~60–80%).

- Factory assembly (unitized) can reduce field waste.

Indoor Environmental Quality (IEQ):

- Window wall can support natural ventilation via operable windows (where allowable).

- Curtain wall is often fixed-glazed, relying more on mechanical ventilation strategies.

En résumé : curtain wall tends to be the simpler route for LEED Gold/Platinum energy performance; window wall can add value for ventilation-focused design.

Can I use window wall in seismic zones?

Yes—if it’s detailed for drift. In higher seismic zones (often cited as D–E), designs commonly require:

- Enhanced joint movement capacity (to accommodate roughly ±1–2% story drift, per engineering)

- Structural silicone glazing to allow controlled movement at the glass/frame interface

- Sliding anchors at head/sill to permit movement without frame distortion

Impact sur les coûts : seismic detailing can add ~15–25% vs standard window wall.

Alternative: curtain wall systems often manage seismic movement more predictably when engineered as a façade system, and can be more economical in high seismic conditions despite a higher base system cost.

What about smoke control and fire spread?

Window wall: often has an advantage because the slab edge compartmentalizes floors, limiting vertical smoke migration along the façade when detailed correctly.

Curtain wall: typically requires more engineered fire/smoke detailing:

- Continuous façade cavities can create vertical smoke paths

- Nécessite fire-stop + smoke seal at each floor line

- May require NFPA 285 compliance for exterior wall assemblies (especially for buildings >40 ft where combustible components are present)

Cost impact (typical budgeting concept): curtain wall fire/smoke systems can add roughly $10–15/linear ft × building perimeter × number of floors (project-dependent).

Always coordinate early with the façade consultant, fire protection engineer, and the AHJ to confirm the required assembly and testing path.